Extraction Process of Volatile Oil of Artemisiae Scopariae Herba

Zhaofeng LI

Department of Pharmacy, Attached Mental Health Center, Tongji Medical College of Huazhong University of Science and Technology, Wuhan 430022, China

Abstract [Objectives] To obtain the optimal extraction process parameters of volatile oil of Artemisiae Scopariae Herba. [Methods] The controlled variable method was used to take the extraction amount of volatile oil as the evaluation indicator, and the effects of single factor solid-to-liquid ratio, soaking time and extraction time on the yield rate of volatile oil were investigated. [Results] When the solid-to-liquid ratio reached 1∶12, the soaking time reached 3 h, and the extraction time reached 2 h, the yield of volatile oil was the highest. [Conclusions] The conditions of this process are stable and feasible, and it is expected to provide a certain reference for extracting volatile oil from Artemisiae Scopariae Herba.

Key words Artemisiae Scopariae Herba, Volatile oil, Extraction process

1 Introduction

Artemisiae Scopariae Herba is the dried leaves ofArtemisiascopariaWaldst.et Kit. orArtemisiacapillarisThunb. It is bitter and spicy in taste and has the functions of clearing away heat and dampness, and treating jaundice. Clinically, Artemisiae Scopariae Herba is used for treating jaundice, urination, dampness, heat and dampness, pruritus and soreness, and it is a commonly used traditional Chinese medicine[1]. Modern studies have shown that Artemisiae Scopariae Herba has a variety of pharmacological activities such as anti-inflammatory, anti-allergic, analgesic, anti-fibrosis, anti-fatigue, anti-tumor, immunity enhancement, and anti-oxidation[2-8].

Artemisiae Scopariae Herba is rich in volatile oils, mainly eucalyptol, camphor, borneol, α-terpineol, caryophyllene oxide,etc.[11]. According to the findings of Liu Xianhuaetal.[12], the volatile oil of Artemisiae Scopariae Herba has significant antibacterial effects onS.aureus,E.coli, andPseudomonasaeruginosa, and the minimum inhibitory concentrations (MIC) onS.aureus,E.coli, andPseudomonasaeruginosaare 0.78, 0.78 and 0.312 μL/mL, respectively. Han Tieetal.[13]carried out antiviral experimentinvitrowith volatile oil from Artemisiae Scopariae Herba and observed its inhibitory effect on respiratory syncytial virus, and found that volatile oil from Artemisiae Scopariae Herba had inhibitory effect on respiratory syncytial virus at the MIC of 3.33 mg/L; You Sixiangetal.[14]studied theinvitroantibacterial effect of wormwood oil as an emulsion and showed that the volatile oil of Artemisiae Scopariae Herba had a significant effect on anthracnose andS.aureusin a concentration range of 0.031 2-2 μL/mL.

In this experiment, we studied the extraction process of volatile oil in Artemisiae Scopariae Herba and explored the extraction process of volatile oil in Artemisiae Scopariae Herba suitable for industrial production. The extraction methods of volatile oil include steam distillation, supercritical carbon dioxide extraction, ultrasonic-assisted extraction, and molecular distillation extraction. In industry, volatile oil is mostly extracted by steam distillation method. Combined with the actual production enterprise, we used common equipment for traditional Chinese medicine production and used steam distillation to extract volatile oil from Artemisiae Scopariae Herba, to obtain the optimal process conditions for industrial production of volatile oil of Artemisiae Scopariae Herba. Verification tests proved the process conditions are feasible.

2 Instruments and test drugs

Instruments: condenser-west tube, round bottom flask, electric heating jacket. Test drugs: Artemisiae Scopariae Herba (provided by Hubei Qichun Yishiyuan Artemisiae Scopariae Herba Product Co., Ltd. in May 2014).

3 Methods and results

3.1Effectsofthesolid-to-liquidratioontheyieldrateofArtemisiaeScopariaeHerbavolatileoilTook 200 g of Artemisiae Scopariae Herba medicinal materials, added 6, 8, 10, 12, 14 times water, soaked for 3 h, extracted by steam distillation for 2 h, collected the volatile oil of Artemisiae Scopariae Herba, calculated the yield rate of volatile oil, and obtained the relationship between the yield rate and the solid-to-liquid ratio. The results are shown in Fig.1.

Fig.1 Effects of the solid-to-liquid ratio on the yield rate of Artemisiae Scopariae Herba volatile oil

From Fig.1, it can be seen that with the increase of the solid-to-liquid ratio, the yield rate of volatile oil increased. When the solid-to-liquid ratio reached 1∶12, the yield rate of volatile oil was the highest.

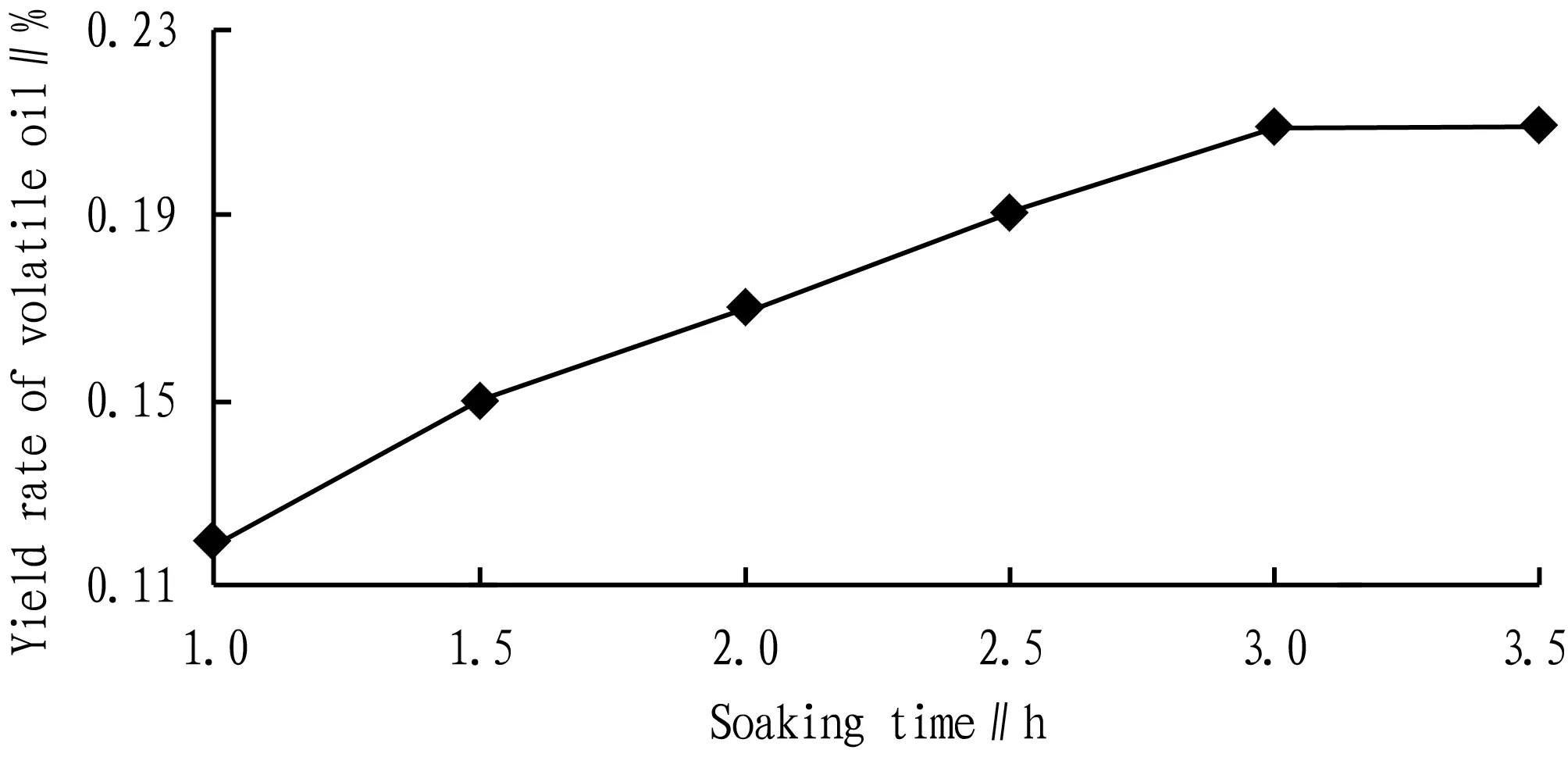

3.2EffectsofthesoakingtimeontheyieldrateofArtemisiaeScopariaeHerbavolatileoilTook 200 g of Artemisiae Scopariae Herba medicinal materials, added 12 times water, soaked for 1, 1.5, 2, 2.5, 3, and 3.5 h, extracted by steam distillation for 2 h, collected the volatile oil of Artemisiae Scopariae Herba, calculated the yield rate of volatile oil, and obtained the relationship between the yield rate and the soaking time. The results are shown in Fig.2.

Fig.2 Effects of the soaking time on the yield rate of Artemisiae Scopariae Herba volatile oil

From Fig.2, it can be seen that with the extension of the soaking time, the yield rate of volatile oil increased. When the soaking time reached 3 h, the yield rate of volatile oil was the highest. Later, even the soaking time increased, the yield rate of volatile oil did not increase.

3.3EffectsoftheextractiontimeontheyieldrateofArtemisiaeScopariaeHerbavolatileoilTook 200 g of Artemisiae Scopariae Herba medicinal materials, added 12 times water, soaked for 3 h, and extracted for 0.5, 1.0, 1.5, 2.0, and 2.5 h, calculated the yield rate of volatile oil, and obtained the relationship between the yield rate and the extraction time. The results are shown in Fig.3.

Fig.3 Effects of the extraction time on the yield rate of Artemisiae Scopariae Herba volatile oil

From Fig.3, it can be seen that with the extension of the extraction time, the yield rate of volatile oil increased. When the extraction time reached 2 h, the yield rate of volatile oil was the highest. Later, even the extraction time increased, the yield rate of volatile oil did not increase.

The results showed that the appropriate amount of Artemisiae Scopariae Herba medicinal materials was taken, soaked in 12 times water for 3 h, and extracted by steam distillation for 2 h. Such process of collecting Artemisiae Scopariae Herba volatile oil is reasonable and feasible.

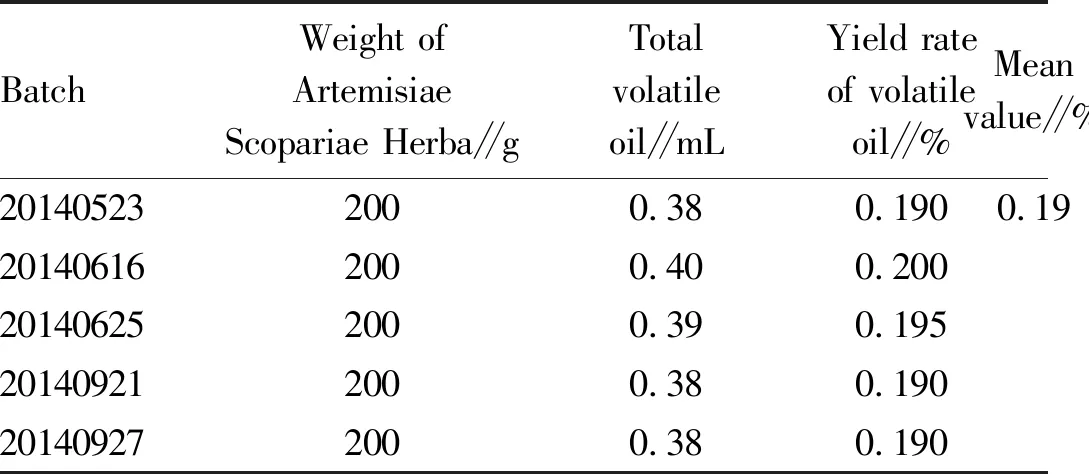

3.4VerificationtestTook 200 g of Artemisiae Scopariae Herba medicinal materials, added 12 times water, soaked for 3 h, and extracted by steam extraction method for 2 h, collected extracted volatile oil, and used the residue for extracting Artemisiae Scopariae Herba acid and Artemisiae Scopariae Herba flavone. The experimental results are listed in Table 1.

Table 1 Results of verification test for volatile oil of Artemisiae Scopariae Herba

BatchWeight ofArtemisiaeScopariae Herba∥gTotalvolatileoil∥mLYield rateof volatileoil∥%Meanvalue∥%201405232000.380.1900.19201406162000.400.200201406252000.390.195201409212000.380.190201409272000.380.190

Through verification in accordance with the above process conditions, the average yield rate of the volatile oil from Artemisiae Scopariae Herba was 0.19%. These indicate that the process conditions for extracting volatile oil from Artemisiae Scopariae Herba are as follows: appropriate amount of Artemisiae Scopariae Herba, 12 times water, 3 h of soaking time, steam extraction for 2 h.

4 Conclusions and discussions

In the experiment, it is found that with the increase of the solid-to-liquid ratio, the yield rate of volatile oil increased. When the solid-to-liquid ratio reached 1∶12, the yield rate of volatile oil was the highest. However, when the solid-to-liquid ratio continued to increase, the yield rate of volatile oil did not increase, indicating that large volume of water solvent made the volatile oil get dissolved in the solvent, accordingly reducing the yield rate. Besides, with the extension of the soaking time, the yield rate of volatile oil increased. When the soaking time reached 3 h, the yield rate of volatile oil was the highest. However, when the soaking time continued to increase, the yield rate of volatile oil did not increase, indicating that the soaking time is not a significant factor influencing the yield rate of volatile oil. The soaking time is a factor that can be flexibly adjusted in the production process according to the actual production conditions. In addition, with the extension of the extraction time, the yield rate of volatile oil increased. When the extraction time reached 2 h, the yield rate of volatile oil was the highest. However, when the extraction time continued to increase, the yield rate of volatile oil did not increase, indicating that the after extraction time exceeds 2 h, if continuing to increase the extraction time, it will increase the production cost.

- Medicinal Plant的其它文章

- Study on Chemical Constituents of Ethanol Extract from Yao Medicine Cissampelopsis spelaeicola

- Comparative Identification between Kadsura coccinea and Kadsura heteroclite

- Comparison of Polysaccharides Content among Common Fruits

- Systematic Review and Meta-analysis of Tanshinone Capsule in the Treatment of Polycystic Ovary Syndrome

- Optimization of Extraction of Total Flavonoids from HERBA BLUMEAE RIPARIAE Using Response Surface Methodology

- Determination of Bisoprolol Fumarate by Fluorescence Quenching Method