Static and Dynamic Combustion Performance of 4-Perforated Gun Propellants

LI Zi-chao, YAO Yue-juan, XU Zhen-zhen, YU Hui-fang, GOU Yong-liang, MA Fang-sheng, YAN Wei,WEI Lun, WANG Feng, LIU Bo, ZHENG Shuang, LI Qiang, LIU Shao-wu, WANG Qiong-lin, WANG Shu

(1.Xi′an Modern Chemistry Research Institute, Xi′an 710065, China;2.China International Engineering Consulting Corporation, Beijing 100048, China;3.Science and Technology on Transient Impact Laboratory, Beijing 102202, China)

Abstract:To increase the burning progressivity and internal ballistic performance of small arms gun propellants, multi-hole gun propellants with 4-perforations are deployed, and the static & dynamic combustion performance are investigated. A closed-bomb is used to test the static combustion performance, and 5.8mm testing guns are used to test the dynamic combustion performance. The results show that, without deterring, the progressivity of 4-perforated gun propellant is better than that of oblate ball and 1-perforated gun propellants. The muzzle velocity of oblate ball and 1-perforated gun propellants are 17m/s and 40m/s lower than that of 4-perforated gun propellant, respectively. The light transmittance of oblate ball and 1-perforated gun propellants are 18% and 15% lower than that of 4-perforated gun propellant, respectively. The static and dynamic results show that 4-perforated gun propellants have better progressivity and internal ballistic performance than those of oblate ball and 1-perforated gun propellants.

Keywords:physical chemistry; 4-perforated gun propellants; static combustion; transmittance; deterrent

Introduction

Gun propellants are mixtures of energetic chemicals and a small amount of inert chemicals designed to burn at the proper rate to propel the projectile from a gun[1-3]. At present, most of gun propellants used in small calibre ammunition are made in three forms: ball propellants[4], oblate propellants (or circular flakes)[5-6], and 1-perforated small cylinders[1,7]. In the cartridge of M16 rifles, the loaded propellants are ball propellants[4], which derived from both nitrocellulose and nitroglycerine. Ball propellants are high in loading density and suitable for mass production. Snipe guns and competitive guns are in favor of 1-perforated gun propellants which usually exhibit high-accuracy and good stability in shooting[7]. Guns with short barrel lengths are in favor of oblate ball propellants which produce scarce residues after gun firing[5-6].

The ballistic efficiency of barrel arms including small calibre arms is greatly affected by the geometry of gun propellants. For example, the ballistic efficiency of 1-perforated gun propellants is better than that of ball propellants and oblate propellants. And multi-perforated propellants such as 7-perforated and 19-perforated gun propellants have better ballistic efficiency than 1-perforated gun propellants[1]. Although multi-perforated gun propellants show better ballistic efficiency over 1-perforated propellants and ball propellants, they can be hardly loaded in the cartridges of small calibre arms due to the large size.

Recently, a new type of 4-perforated gun propellant for small arms has been reported[8-9]. The newly developed propellant shape is based on almost cubic grain geometry with 4 perforations, and has a much higher progressivity at same high gravimetric density as ball propellants[8]. Xu calculated the shape function and combustion performance of 4-hole cuboid gun propellant.

In this study, the performances of a 4-perforated gun propellant, such as static and dynamic combustion, muzzle flash and smoke are investigated. The 4-perforated gun propellants show good burning progression and ballistic performance. This new kind of gun propellants is a good choice for small calibre ammunition, such as 5.56mm (5.8mm), 7.62mm and other small calibre ammunition.

1 Experiments

1.1 Materials

Absorbent propellant containing nitrocellulose (NC), nitroglycerin (NG), 1,5-diazido-3-nitrazpent (DIANP) and 2# centralite (C2) were purchased from Luzhou North Chemical Co. Ltd. Cyclotrimethylene trinitramine (RDX) was purchased from Yingguang Chemical Co. Ltd. Dioctyl phthalate (DOP) was purchased from Sinopharm Chemical Reagent Co., LTD. NA Polymer deterrent, was received from Xi′an Modern Chemistry Institute. The main formulations of 4-perforated gun propellants (mass fraction) are: NC, 69.5%; NG, 10.0%; DIANP, 8.0%; RDX, 10.0%; DOP, 1.0%; C2, 1.5%.

Solvent: ethyl alcohol (CP), acetone (CP) and ethyl acetate were purchased from Xilong Scientific Company.

1.2 Sample preparation

Absorbent propellants, RDX, DOP and mixed solvent were stirred in a blade incorporator with thermostatic water bath for 40—60min, and propellant gels were obtained. The gelled mixtures were extruded through 4-perforated dies. The 4-perforated gun propellants were cut into suitable length and dried in water bath oven for 48hours. To make deterred 4-perforated gun propellants, the as-prepared 4-perforated gun propellants granules were then immersed into NA deterrent/ethyl acetate/water mixtures for 120min, then dried. By changing the content of deterrent, different samples were prepared, i.e. D-0 (no deterrent), D-1 (0.6%), D-2 (1.0%), D-3 (1.4%), D-4 (1.8%).

1.3 Closed-bomb test

Closed-bomb test was carried out to investigate the static combustion performance. The volume of the closed bomb was 100mL, the loading density of gun propellant was 0.2g/mL, and the ignition pressure was 10MPa using 2# nitrocellulose as the ignition powder. The testing samples were stored at 20℃ for 24hours. After that, the samples were sent to the closed-bomb and ignited by an electric igniter. The pressure-time data in the bomb were recorded by an electric pressure gauge and saved in a computer.

1.4 Ballistic firing

The gun firings were performed in two kinds of 5.8mm test barrels, a short barrel gun with light weight projectile, and a long barrel gun with heavy weight projectile. The projectile velocity at 2meters from the muzzle was measured by a pair of light screen targets. The maximum pressure of bore was measured using the copper cylinder method. The maximum pressures (at 20℃) of testing gun propellants were kept the same (about 300MPa). The charge weight of oblate ball, 1-perforated and 4-perforated gun propellants were 1.70, 1.52, and 1.56g, respectively.

1.5 Flame and smoke tests

The muzzle flame was monitored by a high-speed photography (Vision Phantom V7.1). The transmittance visible light of muzzle smoke was tested using a self-made instrument[10-11]. The muzzle smoke was collected in a box connected to the gun muzzle, and the transmittance of a beam of visible light through the box was tested. According to the Lambert-Beer law, the concentration of a chemical is directly proportional to its absorption of light. Thus the muzzle smoke after gun firing can be characterized by the transmittance of light.

2 Results and discussion

2.1 The shape and size of 4-perforated gun propellants

Using extruding method, double base 4-perforated gun propellants were prepared (see the details in experimental section). Learning from Fig.1(b), the prepared 4-perforated gun propellants have four rounded corners in the cross-section, with 4 equally distributed perforations. Graphite coating is usually used to remove the static electricity and to increase the loading density [see Fig.1(c)]. After graphite coating, the loading density of sample D-0 in a 5.8mm cartridge [see Fig.1(d)] is more than 0.90g/cm3, which is similar to that of 1-perforated gun propellants.

Fig.1 Photos of 4-perforated gun propellants

2.2 The static combustion of different types of small calibre gun propellants

Fig.2 shows theL—Bcurves of oblate ball powder, 1-perforated gun propellants, 4-perforated propellants, all of which have no deterrent.L—Bcurve reflects the relationship between burning vivacity and relative pressure.

Fig.2 Combustion characters of different gun propellants

The results show that, without surface deterring, the burning progression of 4-perforated propellant is better than that of oblate ball propellants and 1-perforated propellants. Oblate ball propellant shows the worst burning progression. TheLvalue (burning vivacity) rises quickly at the early burning process (L: 0—0.1). After reaching the peak pressure, it decreases in a quick speed. The peak ofLvalue of oblate ball propellants is the highest among the three kinds of tested samples, which may be due to that the initial surface area of ball propellant is larger than that of 1-perforated propellants and 4-perforated propellants. Unlike large calibre 1-perforated gun propellants which have platform period during the burning process in close-bomb test[1], the burning vivacity (Lvalue) of 1-perforated propellant used in small calibre arms decreases quickly after reaching the peak. This may be due to that the diameters of perforations (or holes) in small calibre ammunition are very small (<0.2mm), and the spread of flame through the perforations is restricted, leading to that the burning speed of outer surface is faster than that of the inner surface (or pore surface). 4-perforated gun propellants has a platform fromB=0.3 toB=0.6, which suggests that the burning progression of 4-perforated propellants is better than that of oblate ball propellants and 1-perforated propellants. Besides, the peak burning vivacity of 4-perforated propellants is the lowest in the three samples, which is due to that the single granule volume of 4-perforated gun propellant is larger than that of oblate ball and 1-perforated gun propellants, and the initial burning surface area of 4-perforated gun propellants is the lowest in the three samples.

2.3 The effects of deterrent on the static combustion performance

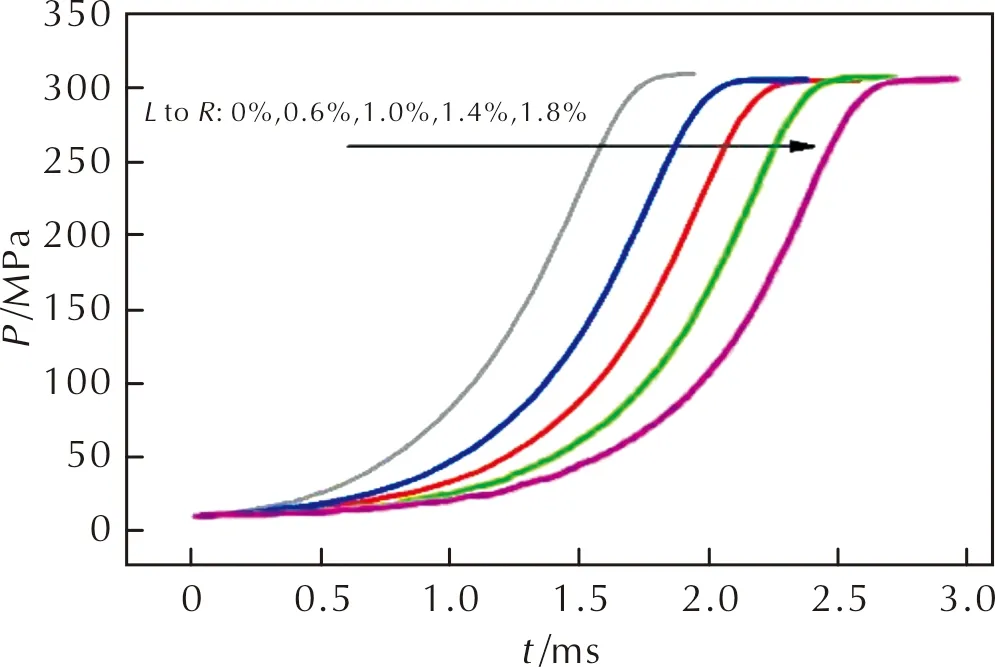

To reduce the maximum pressure of gun barrel, deterrents are usually added in the manufacture of small caliber gun propellants. Besides, the addition of deterrent will change the combustion characteristics and improve the internal ballistic performance. The effect of the content of deterrent on the burning time of 4-perforated gun propellants has been investigated (see Fig.3 and Table 1).

Fig.3 P—t curves of 4-perforated gun propellants with different contents of deterrents

Table 1 Burning time of 4-perforated gun propellants with different contents of deterrents

By increasing the content of deterrent (a polymer deterrent), the burning time tested by the close-bomb is increased. When the contents of deterrent (mass fraction of propellants) are 0, 0.6%, 1.0%, 1.4%, 1.8%, the burning time of 4-perforated gun propellants are 1.94, 2.38, 2.58, 2.72, 2.94ms, respectively. Thus, a small amount of deterrent can greatly increase the burning time of 4-perforated gun propellants.

Besides, the use of deterrent can reduce the initial burning vivacity, and increase the burning progression of 4-perforated gun propellants. Fig.4 shows theL—Bcurves of 4-perforations gun propellants with different contents of deterrents.

The results show that the maximumLvalues or burning vivacity of deterred samples (D-1,2,3,4) are lower than that of sample D-0 having no deterrent. By increasing the content of deterrent, the L value or burning vivacity at the initial stage (B=0—0.3) is decreased. When theBvalue is larger than 0.6, theL—Bcurves of 4-perforations gun propellants with different contents of deterrents tend to be convergent. This may be due to that the diffusing depth of deterrent in the 4-perforated gun propellants is limited, and the inner formulations of the samples with different contents of deterrents tend to the same, leading to that the combustion behaviors of samples with different contents of deterrents tend to be convergent at the late period of burning process.

Fig.4 L—B curves of 4-perforated gun propellants with different contents of deterrents

2.4 Ballistic performance

The gun firings were performed in two kinds of 5.8mm test gun barrels. Oblate ball propellants are used in short gun barrel with light weight projectile, 1-perforated gun propellants are used in long gun barrel with heavy weight projectile, and 4-perforated gun propellants are used in both two kinds of gun barrel. Learning from Fig.5, 4-perforated gun propellants show better internal ballistic performance over oblate ball propellants at all the temperatures (-45℃, +20℃, +50℃), the muzzle velocity increased 17m/s at 20℃. Learning from Fig.6, 4-perforated gun propellants also show better internal ballistic performance over 1-perforated gun propellants, the muzzle velocity increased 40m/s at 20℃.

Fig.5 Internal ballistic results of oblate ball and 4-perforated gun propellants at different temperatures using short gun barrel and light weight projectile

Fig.6 Internal ballistic results of 1-perforated and 4-perforated gun propellants at different temperatures using long gun barrel and heavy weight projectile

2.5 Flame and smoke

Muzzle flame tests are taken in a 5.8mm ballistic gun, a high-speed photography is used to monitor the shooting process. For DBP (Di-butyl phthalate) deterred oblate ball propellant, visual muzzle flame and smoke are captured during gun firing [see Fig.7(a)]. For camphor deterred 1-perforated gun propellants and polymer deterred 4-perforated gun propellants, no muzzle flame are captured [see Fig.7(b) and Fig.7(c)].

Fig.7 Muzzle flames of different gun propellants

For oblate ball propellants, high content of inert DBP (4%—6%) are usually used to decrease the gun pressure and increase the ballistic performance. The static burning time of oblate ball propellant is the longest among the three testing propellants (the static burning time of oblate ball, 1-perforated and 4-perforated testing gun propellants are 3.7, 3.2, 2.9ms, respectively), the burning of oblate ball propellants may be incomplete in the gun barrel, leading to the formation of muzzle flame. For 1-perforate gun propellants and 4-perforated gun propellants, as the burning time are smaller than that of oblate ball propellants, the burning of propellants are complete in the gun barrel, leading to no muzzle flame. Muzzle smoke is collected by a box connected to the gun muzzle, and the transmittance of both visible light is tested. For DBP (Di-butyl phthalate) deterred oblate ball propellant, the transmittance of visible light is 68%. For camphor deterred 1-perforated gun propellants, the transmittance visible light is 71%. For polymer deterred 4-perforated gun propellants, the transmittance is 86%. These results are coincident with the high-speed photography which show that DBP deterred ball propellants and camphor deterred 1-perforated gun propellants have thick muzzle smoke, while polymer (NA) deterred 4-perforated gun propellants have negligible muzzle smoke. This may be due to two reasons. Firstly, unlike DBP and camphor, NA deterrent has no benzene groups, leading to that the oxygen balance of NA is higher than that of DBP and camphor. Besides, the amount of NA (1%—2%) used in 4-perforated gun propellants are less than that of DBP (4%—6%) and camphor (1%—3%).

3 Conclusions

(1) Without deterrents, 4-perforated gun propellants show better burning progression than oblate ball propellants and 1-perforated gun propellants.

(2) 4-perforated gun propellants show better ballistic performance than oblate ball and 1-perforated gun propellants. At room temperature (20℃), the muzzle velocity of 4-perforated gun propellants are 17m/s and 40m/s quicker than that of oblate ball and 1-perforated gun propellants, respectively.

(3) By using a polymer deterrent, 4-perforated gun propellants show less muzzle flame and smoke than DBP deterred oblate ball propellants and camphor deterred 1-perforated gun propellants. The light transmittance of oblate ball and 1-perforated gun propellants are 18% and 15% lower than that of 4-perforated gun propellant, respectively.