Auto-Generation Method of Child Basic Block Structure

WU Sheng(伍 圣), RAO Jue(饒 崛)*, JIANG Xuewei(江學為), ZHONG Anhua(鐘安華), ZHANG Shangyong(張尚勇)

1 School of Textile Science and Engineering, Wuhan Textile University, Wuhan 430200, China

2 School of Fashion, Wuhan Textile University, Wuhan 430073, China

Abstract:In order to realize the auto-generation of clothing paper pattern making and reduce the reliance on the experience of clothing pattern makers, by simulating the experience of the clothing pattern maker through back propagation (BP) neural network, 400 children’s body measurements are collected and drawn into the clothing paper pattern, and the children’s body measurements and the pattern sizes generated through the children’s clothing structure design rules are imported into MATLAB neural network toolbox and a neural network model is established to automatically become the predicted pattern size. Then the parametric mathematical model of children’s clothing paper pattern is established and the children’s body measurements is imported into Auto-CAD parametric function to generate children’s clothing paper pattern automatically. The experimental interface and the virtual try-on interface are demonstrated and their effects are evaluated. The results show that the production rate of clothing paper patterns is improved by the auto-generation method, which is of positive significance to the intelligent production of clothing enterprises.

Key words:paper pattern; back propagation (BP) neural network; Auto-CAD parameterization; auto-generation; virtual fitting

Introduction

With the improvement of people’s living standards and the acceleration of the pace of life, personalized mass customization of clothing will become the future development trend of the clothing industry. The traditional way of clothing production requires high experience of clothing pattern makers, and clothing enterprises spend a lot of manpower and financial resources to train clothing pattern makers. Auto-CAD parametric mathematical model of clothing paper patterns can realize automatic paper pattern generation without the operator learning programming language, which provides an effective way to realize large-scale personalized production of clothing. People generate pattern size by building a back propagation (BP) neural network model and automatically generate garment paper patterns using Auto-CAD parametric functions to automate the production of children’s garment paper patterns.

Compared with traditional manual measurements or 3D body scans, a back-propagation artificial neural network (BP-ANN) based model for body dimensions prediction can predict body dimensions related to pattern making more accurately and efficiently[1]. Maetal.[2]proposed an empirical quantification method and combined it with BP neural network construction to establish a self-learning model for constructing garment pattern designs. A clothing recommendation system was constructed by the convolutional neural network, and the Euclidean distance was used to correct the simulated scoring, which reduced the error between the simulated and real scoring and thus improved the accuracy of the recommendations[3]. The parametric function of Auto-CAD is applied to the automatic generation of clothing paper patterns, with arcs fitting the clothing structure curves, and thus a parametric clothing paper pattern model is created. It provides an effective way for the automatic generation of clothing personalization[4]. Based on the parametric function of Auto-CAD, Lou[5]fitted the waistline with a single circular arc and the hem with a double circular arc to automatically generate A-shaped skirt paper samples, providing theoretical and technical support for personalized mass customization of garment enterprises. It can be concluded that the BP neural network model can be used to predict the size of children’s clothing paper patterns, and the establishment of the BP neural network model to produce children’s clothing paper patterns can improve the production efficiency of apparel enterprises.

Children’s body measurements change rapidly. There have been some studies on BP neural networks applied to clothing structure, but there are few studies on BP neural networks applied to children’s clothing structure. In this paper, we take the Donghua child basic block 2020 edition[6]as an example and establish the neural network model of Donghua child basic block 2020 edition by collecting the body measurements of boys’ standard body type, and MATLAB neural network toolbox[7]is applied to the clothing pattern-making technology to realize the automatic generation of the pattern size. The BP neural network model was established by MATLAB neural network toolbox, and the automatic generation of children’s clothing paper patterns was realized by using Auto-CAD parameterization, which provides a technical reference for the automatic production of clothing paper samples in clothing enterprises.

1 Theory and Methodology

1.1 Theory of BP neural network

BP neural network is a feedback-free forward network in which the neurons are arranged in layers[8]. The neural network does not need to pre-set the functional relationship between input and output parameters, and the output parameters are finally predicted by continuously adjusting the weight coefficients through error BP.

1.2 Method of building BP neural network model for children’s clothing

1.2.1Determinationofthenumberofneurons

A BP neural network consists of one input layer, one or more hidden layers, and one output layer. The number of hidden layers and the number of hidden layer network nodes have a great impact on the network training and learning performance of the neural network. Too few nodes in the hidden layer will lead to insufficient learning ability. Too many nodes in the hidden layer will lead to overfitting of the network. Therefore, it is very important to determine the number of nodes in the hidden layer. In this paper, the formula[9]for determining the number of nodes in the hidden layer network is

(1)

whereyrepresents the number of network nodes in the hidden layer,nrepresents the number of network nodes in the input layer,mrepresents the number of network nodes in the output layer, andais a constant between 1 and 10. In neural networks, one hidden layer is usually given priority, and when one hidden layer is not able to perform the network operation, the number of layers of the neural network is considered to increase appropriately. In this paper, we use a neural network containing one hidden layer.

1.2.2Normalizationofdata

Generally, the output function of neurons is the most sensitive in the range of 0-1. To improve the performance of neural networks, the data are normalized. The normalization formula[10]is expressed as

(2)

whereyidenotes the value mapped to the interval [0, 1],xidenotes the original value,xminis the minimum value of the attribute, andxmaxis the maximum value of the attribute.

1.2.3Experimentalprocedure

The experiment was conducted by collecting body measurements from 400 children aged 3-6 years old, using 320 samples as training samples, 40 samples as validation samples, and 40 samples as test samples. MATLAB has a good programming environment, an easy-to-use high-level language, a powerful data processing capability, good user interfaces, and rich application toolboxes. In this paper, MATLAB is used to implement the prediction of children’s clothing pattern sizes. The neural network is then trained and simulated by calling the neural network toolbox of MATLAB.

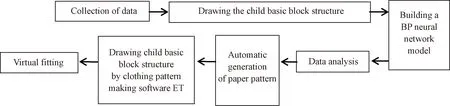

This article draws children’s clothing paper patterns according to the pattern-making rules of the Donghua child basic block 2020 edition. We take the collected standard children’s body measurements as input parameters, draw children’s clothing paper patterns by the standard children’s body measurements, and use their pattern sizes as output parameters to invoke the MATLAB neural network toolbox to build a BP neural network model. The body measurements were then imported into Auto-CAD, and the child basic block structure was automatically generated by the parametric drawing function of Auto-CAD. The article analyzed the data of BP neural network prediction results, and the prediction results were used to draw the child basic block structure with apparel pattern making software ET and imported into virtual fitting software for virtual fitting to evaluate its effect. The experimental flow is shown in Fig. 1.

Fig. 1 Experimental procedure

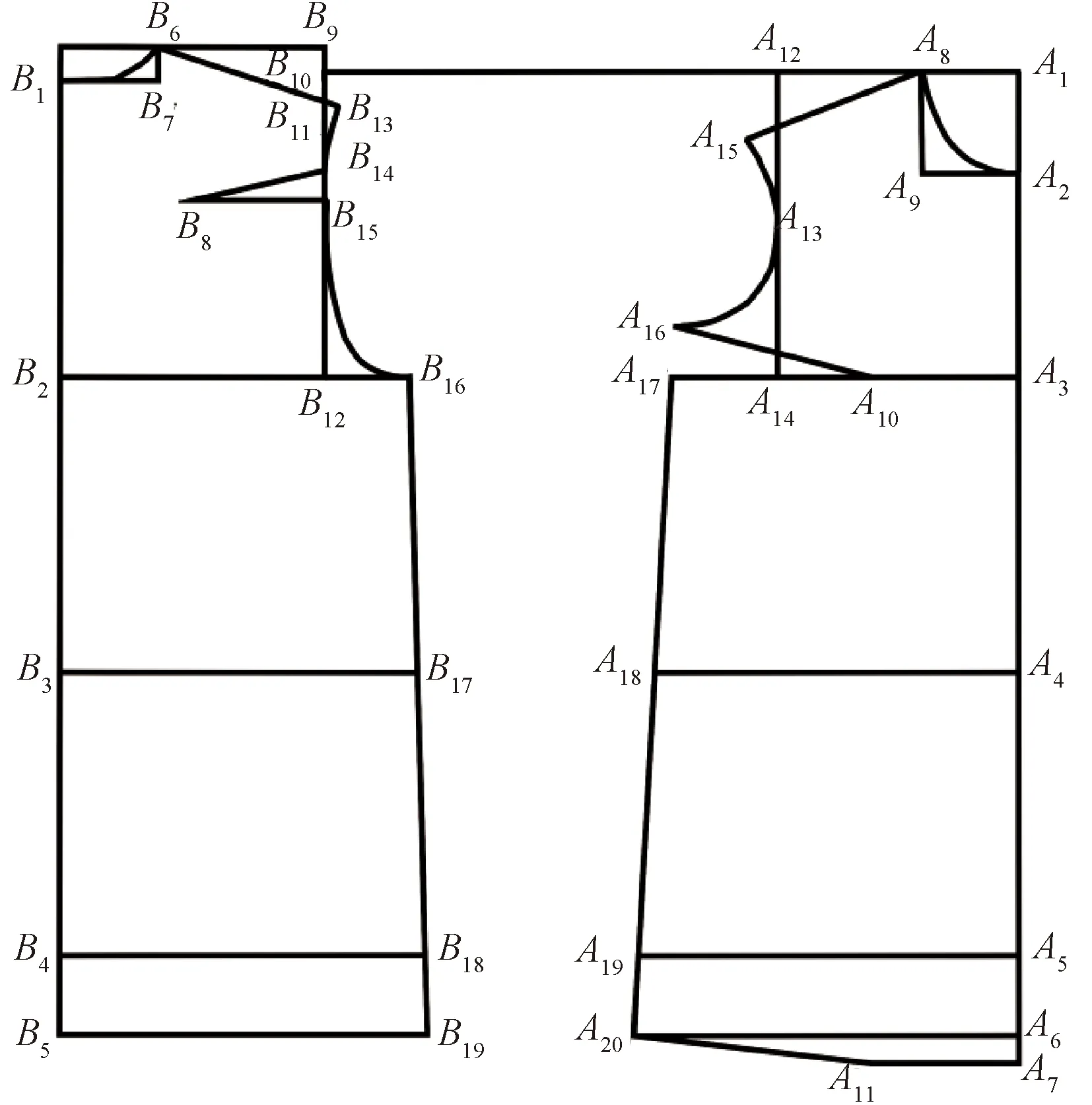

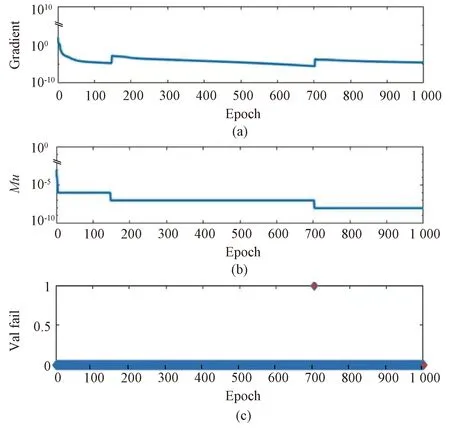

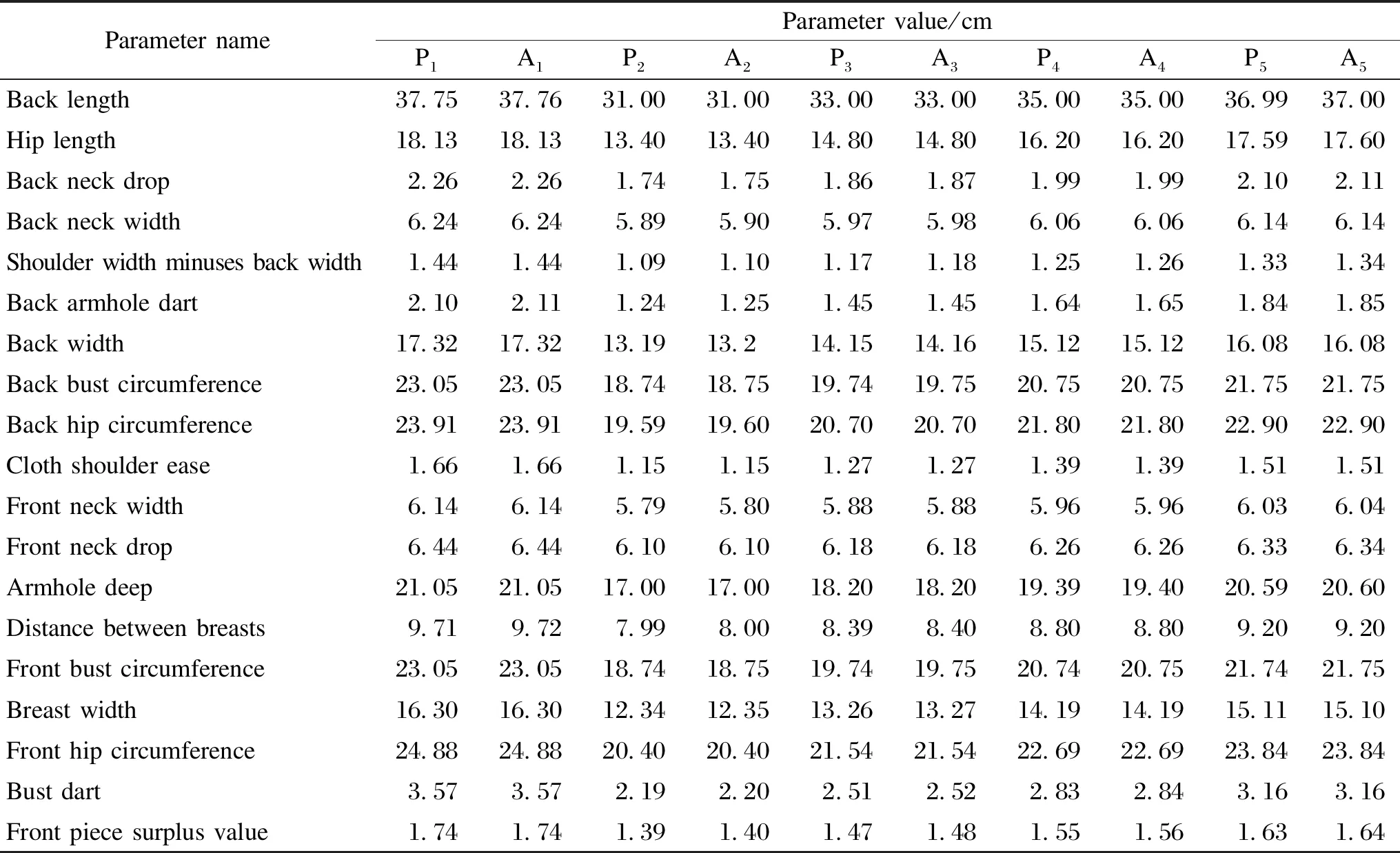

Because the height, chest circumference, and hip circumference of children’s body measurements have the largest correlation factor with the child basic block pattern size, the input parameters are height, chest circumference, and hip circumference. Combined with the rules of child basic block structure design, the output parameters are back length, hip length, back neck drop, back neck width, shoulder width minuses back width, back armhole dart, back width, back bust circumference, back hip circumference, cloth shoulder ease, front neck width, front neck drop, armhole deep, distance between breasts, front bust circumference, breast width, front hip circumference, bust dart, and front piece surplus value. In this paper, we establish a parametric mathematical model to constrain the child basic block structure line parametrically. The constrained parts are shown in Fig.2, and the parameterized constraint names of each part are shown in Table 1.

Fig. 2 Donghua child basic block 2020 edition

Table 1 Parameterized constraint names of each part

2 Results and Discussion

2.1 Data analysis

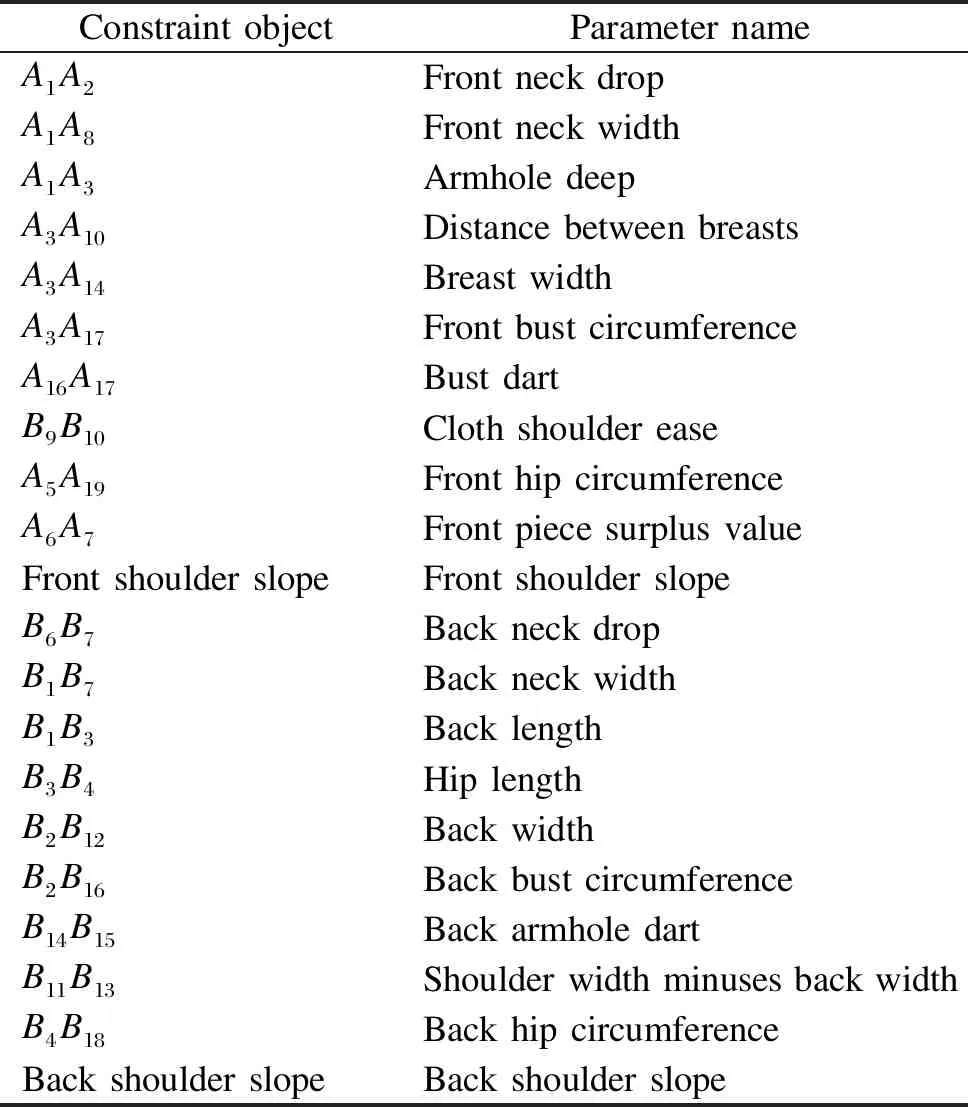

In this paper, the number of neurons in the hidden layer of the neural network model used is 13 according to the formula for determining the number of neurons in the hidden layer neural network. Three input parameters are used as input layer neurons and 19 output parameters are used as output layer neurons. The structure of the BP neural network model is 3×13×19 type.

The MATLAB Neural Network Toolbox trains the input data and output data. The activation function used by the neural network is the Log-Sigmoid function[11], which is a nonlinear transformation function. The neural network uses a nonlinear least squares algorithm, the Levenberg-Marquardt method, to minimize the error of the neural network. The training function is set as the “trainlm” function with a maximum number of iterative steps of 1 000.

Figure 3 is the image of fitting degrees obtained from MATLAB software, whereRrepresents the correlation between the target and output values. The closer theR-value is to 1, the greater the correlation between the target and output values is, and the closer theR-value is to 0, the smaller the correlation between the target and output values is. TheR-values of the training set, validation set, test set, and overall set in Fig. 3 are all 1. It can be concluded that the predicted and output values of the BP neural network model are correlated very well, indicating that the BP neural network fits well and can predict the child basic block pattern size.

Figure 4 shows the iterative training process of the neural network. Gradient denotes the gradient in training, and the training ends when the gradient reaches the expected value. When the number of iterative learning (epoch) is 1 000, the gradient is 2.341×10-5. The training network is controlled by theMuparameter to avoid stopping the training due to oversized parameters. When the epoch is 1 000,Muis 1×10-8. The “val fail” indicates the generalization ability, and the validation check is always 0 during the training process, which means that there is no situation that the error does not decrease but increases during the training process. If the error does not decrease but increases for 6 consecutive times, the training will be terminated to prevent the over-fitting situation. The red marks in Fig. 4(c) show that the validation check is 1 when the number of training steps is 700, and the validation check is 0 when the number of training steps is 1 000. This means that the error of the neural network is decreasing during the training process.

Fig. 3 Image about fitting degrees obtained from MATLAB software

Fig. 4 Iterative training performance chart: (a) gradient change chart; (b) Mu initial value; (c) generalization ability check

By comparing the neural network prediction results with the actual sample results, it can be concluded from Table 2 that the prediction results basically match the actual output results. The predicted parameters of back length, hip length, back neck drop, back neck width, shoulder width minuses back width, back armhole dart, back width, back bust circumference, back hip circumference, cloth shoulder ease, front neck width, front neck drop, armhole deep, distance between breasts, front bust circumference, breast width, front hip circumference, bust dart, front piece surplus value have the maximum errors no more than 0.01 cm which basically has no effect on the child basic block pattern size of the experimental results. The experimental results prove that the BP neural network prediction model fits well, and the BP neural network model for predicting the child basic block pattern size can simulate the clothing paper pattern designer experience.

Table 2 Comparison of predicted and actual sample results

2.2 Auto-CAD parametric drawing clothing structure

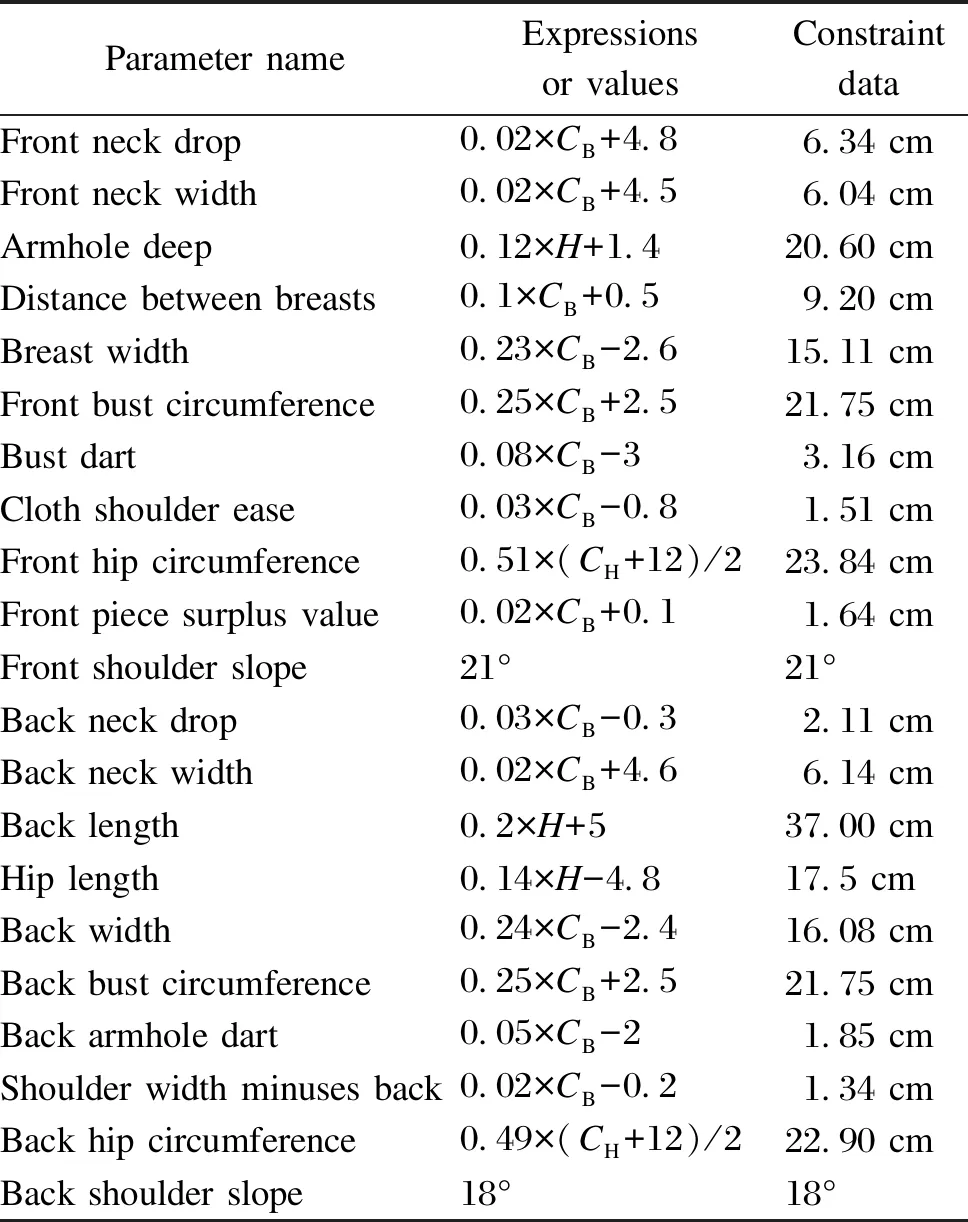

In this paper, we selected a child body measurements and established the parametric constraints of child basic block paper pattern. The child basic block constraint data are shown in Table 3. We imported the children’s body measurements into the parametric function module of Auto-CAD, and established the parametric mathematical model of the child basic block paper pattern through the parametric function of Auto-CAD.

Taking size 160/77 as an example, we use the geometric and labelling constraints of the parameterization function of Auto-CAD to adjust the structure of the child basic blocks. Child basic block paper pattern can be fitted with single arc and double arc to the back collar arc, front collar arc, and armhole arc. The back piece collar arc is constrained by the straight line and the single circular arc curve. The arc of the back body sleeve hole is constrained by the single circular arc and triple circular arc constraint methods. The front piece collar is constrained by double circular arc constraint method. The upper half of the front sleeve hole curve is constrained by a double circular arc, and the lower half is also constrained by a double circular arc.

Table 3 Child basic block constraint data for example 160/77

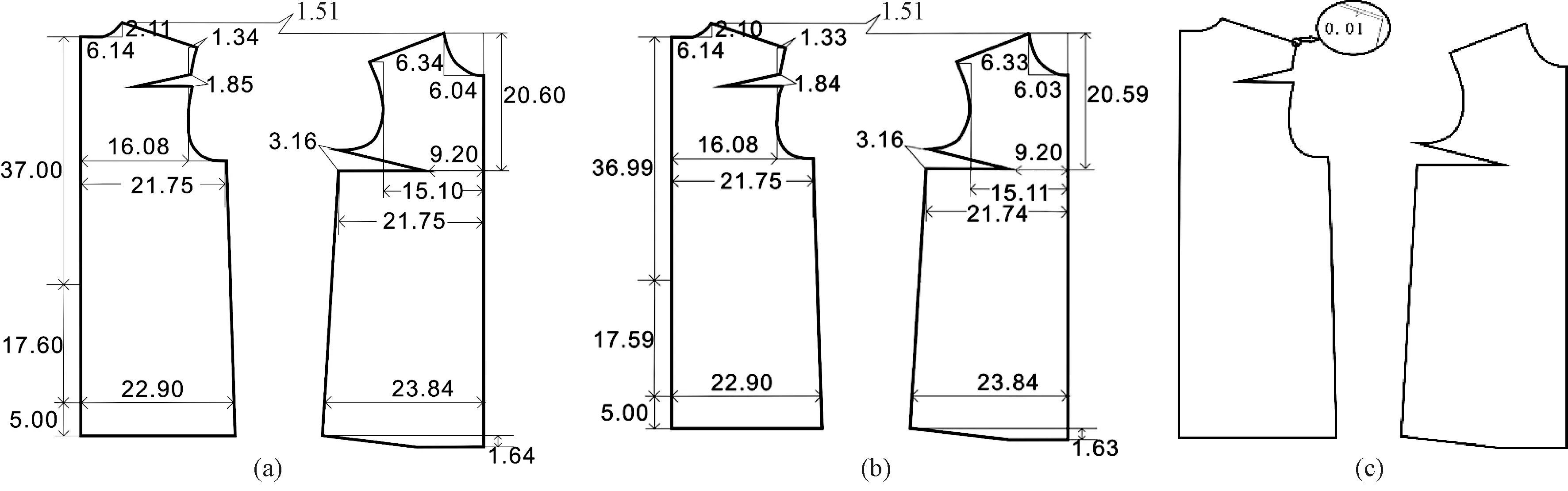

2.3 Analysis of children’s clothing structure

An experimental sample was randomly selected, and the actual measured clothing paper pattern size and the predicted clothing paper pattern size generated by the BP neural network were plotted and compared by the clothing pattern making software ET. As shown in Fig. 5, the structure diagrams drawn according to the actual and predicted parameters are basically identical, and the maximum error of the pattern size is not more than 0.01 cm. After the two charts are overlapped, the lines basically overlap, which meets the expected effect. It is shown that the BP neural network prediction model can predict the child basic block pattern size.

Fig. 5 Structural analysis diagram: (a) actual sample; (b) predicted sample; (c) overlapping

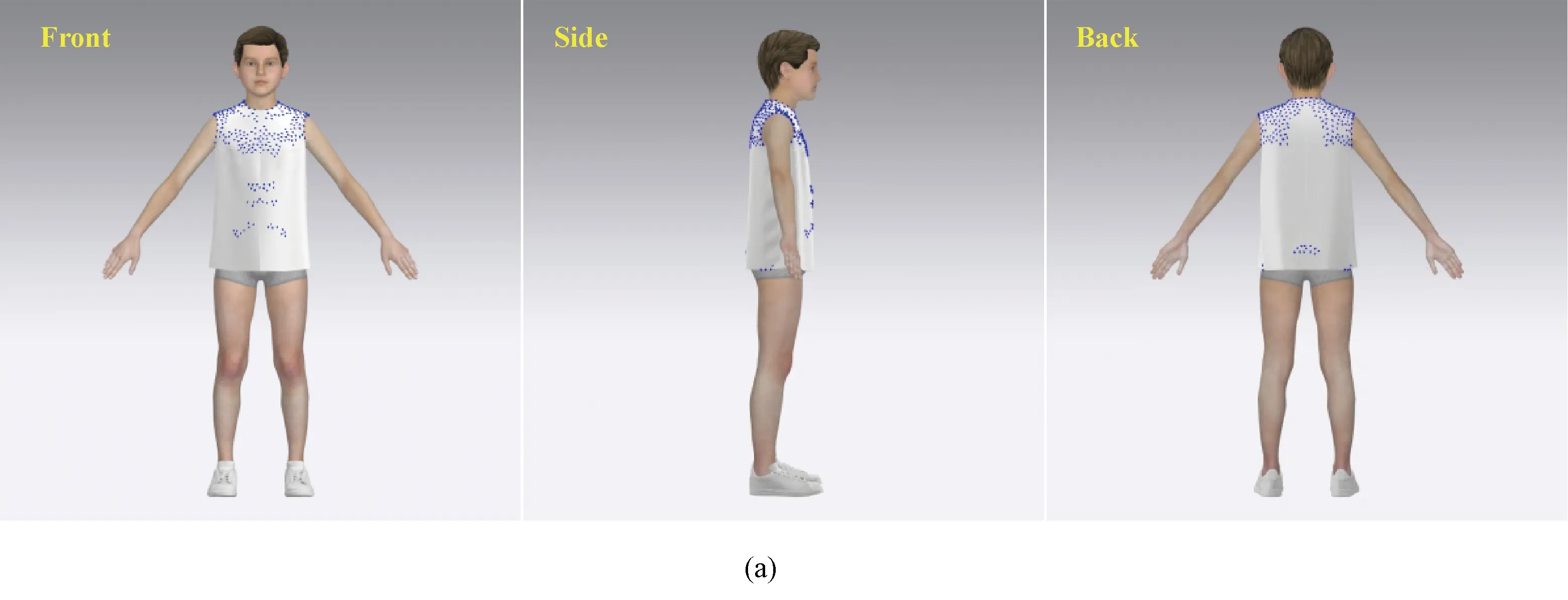

2.4 Virtual fitting

The child basic block structure drawn by ET was imported into the clothing virtual fitting software CLO3D[11], and the display effect was obtained as shown in Fig.6. The blue dots represent the contact points between the clothing and the virtual mannequin. From the front image, it can be seen that the blue dots are evenly distributed, mainly on the chest and shoulders, with a small number of stress points on the protruding part of the abdomen. From the side image, it can be seen that the stress points on the shoulders and hips of the dress are evenly distributed. From the back image, it can be seen that the stress points are evenly distributed on the back and shoulders, with a small number of stress points on the protruding part of the hips. The clothing made from the predicted data and made by the actual pattern maker were analyzed by quantitative comparison. The actual pattern maker made clothing with 192 pressure points on the front chest and shoulders, 39 pressure points on the front abdomen, 192 pressure points on the back and back shoulders, and 18 pressure points on the back hips. Compared with the clothing made by the actual pattern maker, the pressure points in the front chest and front shoulders of the clothing produced by using the predicted data decreased by 14, the pressure points in the front abdomen increased by 8, the pressure points in the back and back shoulders decreased by 5, and no change in the number of pressure points in the back hips, and the pressure points in the front waist increased by 4. This does not affect the comfort and fit of the clothing, and the difference in the number of pressure points is essentially the same as the desired effect of wearing the clothing. This indicates that the children’s clothing made by the established BP neural network prediction model is very close to the results of the clothing made by the actual pattern maker. In summary, the pressure points of children’s clothing were evenly distributed and there were no useless pressure points. The differences between the predicted data and the actual data are not significant, and the clothing made with the predicted data can meet the comfort and aesthetic requirements of children’s clothing, indicating that the established BP neural network model can predict the pattern size of children’s clothing.

Fig. 6 Virtual fitting effect display: (a) actual sample; (b) predicted sample

3 Conclusions

The child basic block structure generated in this paper is well-fitting and ideal for wearing. The experience of the clothing paper pattern designer was simulated by BP neural network, and the automatic generation of clothing structure was realized by the parameterization of Auto-CAD. The accuracy of the BP neural network prediction results was analyzed through experimental data, and the clothing fit and aesthetics were demonstrated in the virtual fitting interface, which provided a theoretical basis for mass personalization of clothing.

Automated production of clothing will become the development trend of future clothing enterprises, and the combination of computer and clothing production will create greater benefits for clothing enterprises. In this paper, only children’s clothes are studied. Further research is needed on the method of generating skirts and pants for children. The established BP neural network model of children’s clothing realizes the automatic generation of children’s clothing pattern size, which gets rid of the reliance on the experience of clothing pattern makers, and the parameterization function of Auto-CAD realizes the automatic generation of children’s clothing structure, which will save a lot of time for the clothing enterprises.

Journal of Donghua University(English Edition)2023年2期

Journal of Donghua University(English Edition)2023年2期

- Journal of Donghua University(English Edition)的其它文章

- Simultaneous Morphologies and Luminescence Control of NaYF4∶Yb/Er Nanophosphors by Surfactants for Cancer Cell Imaging

- Porous Graphene-Based Electrodes for Fiber-Shaped Supercapacitors with Good Electrical Conductivity

- Fabrication of High-Efficiency Polyvinyl Alcohol Nanofiber Membranes for Air Filtration Based on Principle of Stable Electrospinning

- Construction of Oriented Structure in Inner Surface of Small-Diameter Artificial Blood Vessels: A Review

- Small Amplicons Mutation Library for Vaccine Screening by Error-Prone Polymerase Chain Reaction

- Proportion Integration Differentiation (PID) Control Strategy of Belt Sander Based on Fuzzy Algorithm