Effects of Assistant Solvents and Mixing Intensity on the Bromination Process of Butyl Rubber*

Effects of Assistant Solvents and Mixing Intensity on the Bromination Process of Butyl Rubber*

WANG Wei (王偉)1,2, ZOU Haikui (鄒???1,**, CHU Guangwen (初廣文)1,2, XIANG Yang (向陽)1, PENG Han (彭晗)1and CHEN Jianfeng (陳建峰)1,2,**1Research Center of the Ministry of Education for High Gravity Engineering and Technology, Beijing University of Chemical Technology, Beijing 100029, China

2State Key Laboratory of Organic-Inorganic Composites, Beijing University of Chemical Technology, Beijing 100029, China

A slow bromination process of butyl rubber (IIR) suffers from low efficiency and low selectivity (S) of target-product. To obtain suitable approach to intensify the process, effects of assistant solvents and mixing intensity on the bromination process were systemically studied in this paper. The reaction process was found constantly accelerated with the increasing dosage and polarity of assistant solvent. Hexane with 30% (by volume) dichloromethane was found as the suitable solvent component, where the stable conversion of 1,4-isoprene transferring to target product (χA1s) of 80.2% and the corresponding S of 91.2% were obtained in 5 min. The accelerated reaction process was demonstrated being remarkably affected by mixing intensity until the optimal stirring rate of 1100 r·min?1in a stirred tank reactor. With better mixing condition, a further intensification of the process was achieved in a rotating packed bed (RPB) reactor, where χA1sof 82.6% and S of 91.9% were obtained in 2 min. The usage of the suitable solvent component and RPB has potential application in the industrial bromination process intensification.

bromination of butyl rubber, process intensification, assistant solvent, mixing intensity

1 INTRODUCTION

Bromobutyl rubber (BIIR) is produced via the bromination of butyl rubber (IIR), which brings active C Br bonds into the polymer. BIIR has not only the same advantages as IIR (excellent gas tightness and chemical stability), but also better performance on vulcanizing and compounding than that of IIR [1-4]. Therefore, BIIR has been widely used in the field of tires, protective clothing, medical supplies etc., as the substitute of IIR [5, 6]. Bromination of IIR is usually carried out in the solution of IIR because the product in solution process is more homogeneous than that in mixing process of dry IIR [7-9].

The essence of the IIR bromination is an ionic substitution reaction where Br2(B) is polarized to ions and then reacts with 1,4-isoprene unit (1,4-IP, A) in IIR [5, 10-12]. This substitution reaction can be simply displayed by Eq. (1), where the target units [exo-allylic bromide structures (EXO) with C Br bonds and double bonds of carbon] in product is expressed as P and the by-product HBr is expressed as C [10].

The presence of by-product C results in an addition reaction as Eq. (2), where D is the undesired units (saturated 1,4-IP units with C Br bonds but without double bonds of carbon) in product.

The reaction in Eq. (2) results in a decrease of product purity and product unsaturation degree, and a low utilization of A [2-5, 10]. Therefore, Eq. (1) is called as the main reaction and Eq. (2) is regarded as the side reaction in this work. Oxidant, such as NaClO solution with low concentration, can be used to retransform C to B, resulting in the increase of B utilization and the reduction of side reaction [6, 10, 13]. However, the overall rate of the bromination is slow, which provides probability to Eq. (2), and then the bromination process still suffers from low selectivity (S) of P [10]. Kaszas [14] reported that the overall bromination rate is controlled by rate of the main reaction. Meanwhile, the addition of dichloromethane (DCM), as an assistant solvent for the traditional solvent hexane (Hex.), is found available to accelerate Eq. (1). Then, highly uniform BIIR product can be obtained via the accelerated bromination process. However, a systematic study about the effect of DCM dosage on the bromination reaction process has not been reported and a selection criterion of assistant solvent is desired.

The Eq. (1) accelerated by suitable assistant solvent is a rapid reaction [10], which may be affected by mixing conditions of reactants. Yang and Chen [15-17] have reported that the apparent reaction rates of instantaneous (extremely rapid) reactions such as crystallization, precipitation and cationic polymerization are remarkably affected by mixing, resulting in the decrease of production efficiency or product quality. It has never been reported that whether the apparent rate of the bromination reaction is affected by mixing. Therefore, an investigation on the effect of mixing conditions on the bromination process is necessary.

The objective of this work was to systemically

* Supported by the National Natural Science Foundation of China (21176014, 20990221, 21121064) and the Science-Technology Project for Supervisors of Excellent Doctor Degree Thesis of Beijing (20111001001).

** To whom correspondence should be addressed. E-mail: zouhk@mail.buct.edu.cn; chenjf@mail.buct.edu.cninvestigate the effects of solvents (including the dosage and type of assistant solvent) and mixing intensity on the bromination reaction process with an attempt to intensify the bromination process via catalyzing the reaction and enhancing the mixing. More specifically, optimum dosage and selection criteria of assistant solvent were determined via contrast experiments in a stirred tank reactor (STR). The performance of a rotating packed bed (RPB) with high-intensity and high-efficiency mixing [16-24], as a bromination reactor, has been shown on the basis of demonstrating the significant effect of mixing in the STR.

2 EXPERIMENTAL

2.1 Materials

IIR (1,4-IP content is 1.67%, by mole) and bromine (purity≥99.5%) were purchased from Zhejiang Cenway New Materials Co. Ltd. and Sino Pharm Chemical Reagent Co. Ltd in China, respectively. Solvents including hexane (Hex.), dichloromethane (DCM), chloroform (THMS) and carbon tetrachloride (CTC) were purchased from Beijing Chemical Works in China with purity of more than 95.0%. Sodium hypochlorite solution (available chlorine content≥5%, Tianjin Guang-fu Chemical Research Institute, China), sodium hydroxide (purity>95.0%, Beijing Chemical Works, China) and chloroform-D [99.8%D+0.03% (by volume) TMS, Qingdao Tenglong Weibo Technology Co. Ltd., China] were also used.

2.2 Experimental procedures

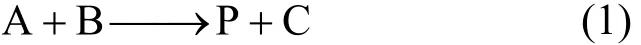

Two kinds of bromination reactor with different mixing conditions, STR and RPB, were used to study the effects of mixing intensity on the bromination. The STR and RPB have been schematically shown in Fig. 1. The STR was mainly comprised of a 500 ml brown glass reactor equipped with a mechanical stirrer. Diameter of the STR was 10 cm and diameter of the crescent shaped Teflon stirring blade in the STR was 6 cm. The RPB was mainly comprised of a packed rotator in a 3000 ml fixed casing. The radial thickness and axial depth of the packed rotator were 50 mm and 53 mm, respectively. The experimental procedures in the two reactors can be described as follows.

In the STR, the bromination process was batch operation. IIR was dissolved in 200 ml solvent and sodium hypochlorite solution was added before the bromination was started by the injection of bromine solution, which was dissolved in 20 ml hexane. The initial concentrations of A, B and NaClO were set as cA0=20 mmol·L?1, cB0=10 mmol·L?1and cNaClO=20 mmol·L?1, respectively. The bromination proceeded for time (t) of 0.17-30 min at 25 °C, and then was terminated by the addition of sodium hydroxide solution. As following, the bromination system was washed by distilled water to remove inorganic salt and the residual sodium hydroxide, and was dried in a vacuum drying oven at 60 °C. The dried samples were characterized to obtain the conversion of A (χA) at the corresponding t. The variation of χAwith increasing t expressed the bromination reaction process. Different bromination parameters in Experiment groups (Exp. 0-9), including details of solvent and rotating speed (N) of the mechanical stirrer, were shown in Table 1 and were respectively used to study their effects on the bromination reaction process.

Figure 1 Schematic diagrams of bromination reactors

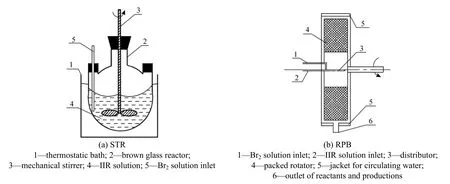

Table 1 Parameters in the experiment groups (cA0=20 mmol·L?1, cB0=10 mmol·L?1, cNaClO=20 mmol·L?1, T=25 °C)

The bromination process in the RPB was continuous operation [18]. Solutions of A and B were prepared respectively before being pumped into the inlets [1 and 2 in Fig. 1 (b)] with respective volume flow rates of 500 ml·min?1and 50 ml·min?1. These two solutions met in the distributor [3 in Fig. 1 (b)] and jetted onto the inner edge of the rotator [3 in Fig. 1 (b)], followed by flowing through the packing and exiting the RPB. The initial concentrations of A, B and NaClO in the RPB were controlled at the same values as those in the STR. Other bromination parameters such as the details of solvent, the rotating speed (N) of the rotator and the temperature were maintained constant and listed in Table 1 (Exp. 10). The residence time of reactants in the RPB (t0), which is also the bromination time in the RPB, remained stable and was less than 1 s [18]. The solution from the RPB was then led into brown beakers where bromination continued without stirring for a period of time (t′), ranging from 0 to 3.0 min. NaOH solution was subsequently added into these beakers to terminate the bromination. The post treatments for the terminated bromination system and the characterization of samples were the same as those in the STR experiments. The total bromination reaction time (t) is the sum of t0and t′. The t0was very short and constant, while t′ was changed to study the variation of χAwith increasing time, which represented the bromination reaction process with mixing in the RPB. At each t′, three samples were collected and characterized. The results adopted in the paper were from the three samples with an error range of ±5%.

2.3 Characterization and calculation

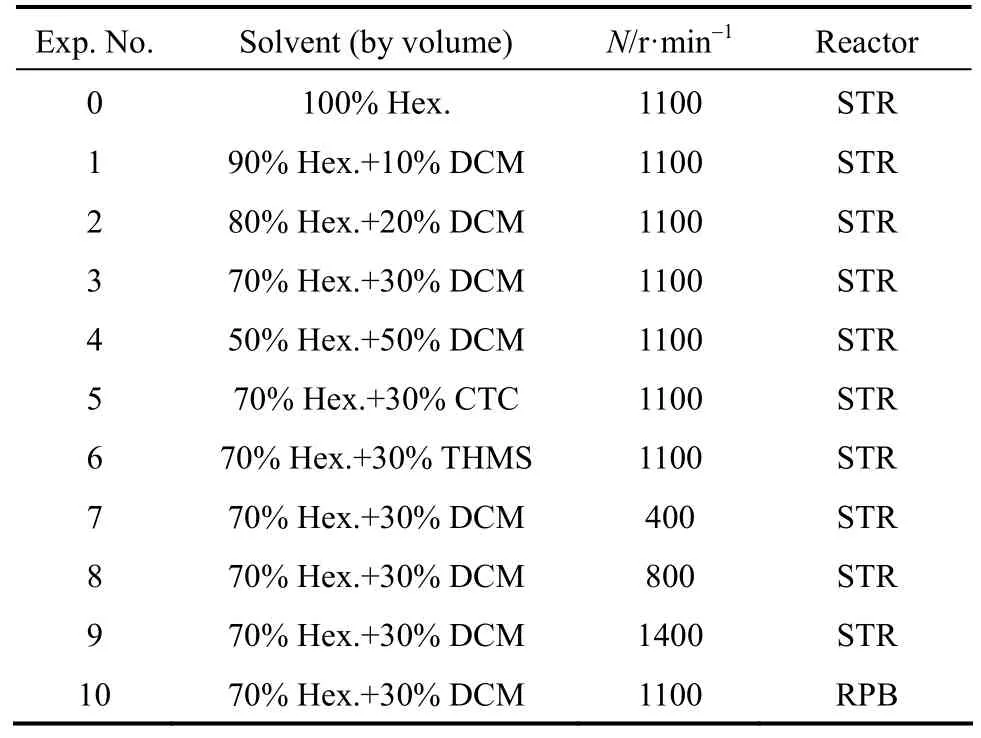

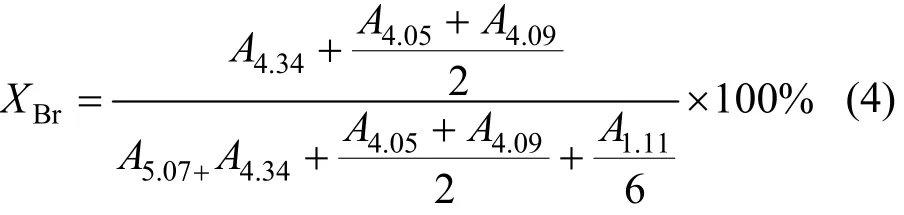

The dried samples were dissolved in chloroform-D for NMR analyses with a Bruker AV400MHz spectrometer. The content of A in the brominated samples (XA) can be calculated by Eq. (3), where Aχis the integral area of the characteristic peak with chemical shift χ (χ=1.11, 4.05, 4.09, 4.34, 5.02, 5.07, 5.40 ppm) in 1H-NMR spectra of the samples [2, 5, 25, 26]. Analogously, the content of bromine with the EXO structure and the rearranged EXO structure in the brominated samples (XBr) can be determined by Eq. (4).

As the index of the bromination reaction process, conversion of A (χA) is determined by Eq. (5), where XA0is content of A in the IIR without bromination (1.67%, by mole), χA1is the conversion of A transferring via Eq. (1) and χA2is the conversion of A transferring via Eq. (2). χA1and χA2are calculated by Eqs. (6) and (7), respectively. The selectivity of target-product P (S) is calculated by Eq. (8).

3 RESULTS AND DISCUSSION

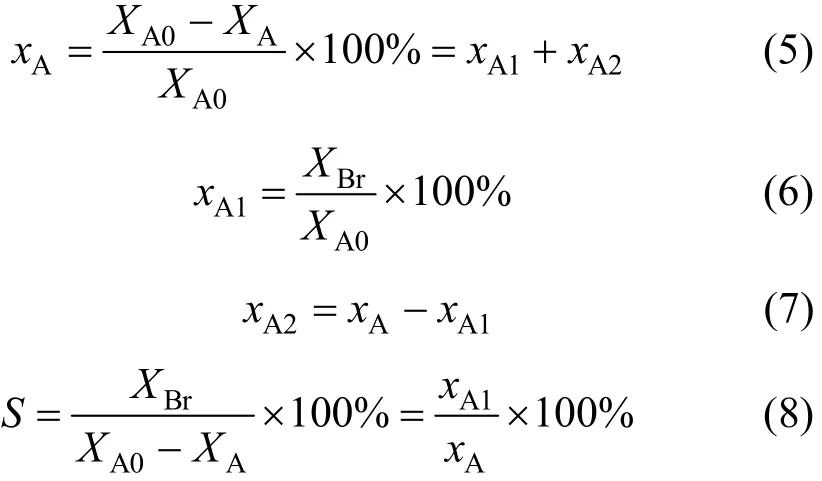

3.1 Bromination process of IIR without assistant solvent

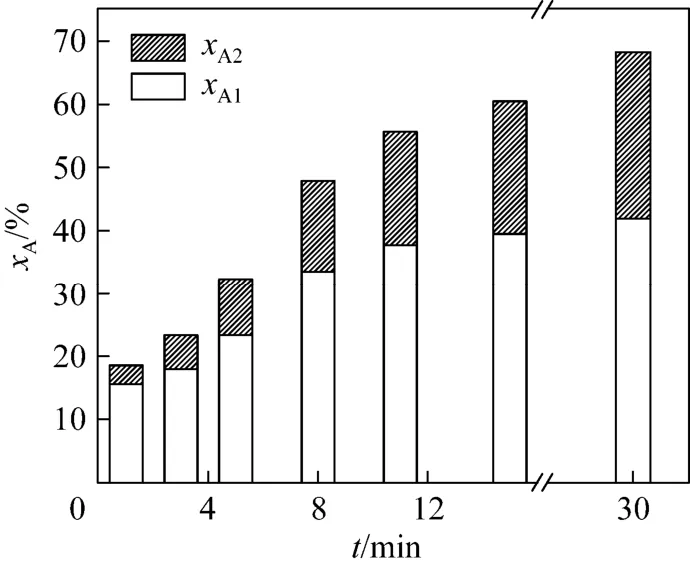

As the bromination process of IIR without assistant solvent, a reference for comparison, the result of Exp. 0 in Table 1 is shown in Fig. 2. It is observed that the total conversion of A increases gradually from 18.6% to 68.3% with increasing time from 1 to 30 min. During this course, the increase of χA1is quite slight when t is more than 15 min, while χA2increases all the time. The selectivity of target-product, S, in this experiment group is listed in Table 2 with the corresponding t. It is found that S constantly decreases with the increasing t, and reaches to 65.3% when t is 15 min, from where the increase of χA1almost stops. These results indicate that the apparent reaction rate of Eq. (1) is slow. The slow main reaction needs a longreaction time, and then provides more opportunity to the side reaction, which means the increase of by-product quantity, the decreases of S and product quality, low raw material conversion rate and production efficiency [10]. Therefore, it is necessary to attempt to intensify the bromination process via accelerating the apparent reaction rate of Eq. (1).

Figure 2 Variation of xA(xA1+ xA2) with t (Exp. 0 in Table 1)

Table 2 Selectivity (S) at the bromination time t in every experiment group

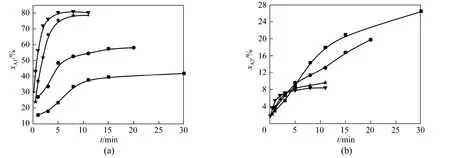

Figure 3 (a) xA1vs. t and (b) xA2vs. t with different DCM content in solventssolvent (by volume): ■ 100% Hex. (Exp. 0); ◆ 90% Hex. + 10% DCM (Exp. 1); ▲ 80% Hex. + 20% DCM (Exp. 2); ▼ 70% Hex. + 30% DCM (Exp. 3);50% Hex. + 50% DCM (Exp. 4)

3.2 Bromination processes of IIR in solvents with different DCM content

The bromination processes of IIR in solvents with different DCM content (φDCM) are shown in Fig. 3, which are the results of Exps. 0-4. In Fig. 3 (a), it is observed that χA1increases with increasing time until approaches to an approximate stable value. The stable value of χA1(χA1s) obviously increases from 39.5% to 80.2% with increasing φDCMfrom 0 to 30%, while the time is reduced from 15 to 5 min when χA1approaches to the stable value (ts). These results indicate that the Eq. (1) can be accelerated by using DCM as assistant solvent, and this accelerating effect can be enhanced by increasing DCM content in the solvent. The reaction (1) [Eq. (1)] is an ionic substitution where Br2is firstly polarized to ions and then reacts with 1,4-IP [5, 12]. As a solvent with polarity of 3.40, DCM is helpful for the polarization of Br2and then available for accelerating the reaction (1). As φDCMincreased, polarity of the solvent increased and the accelerating effect was enhanced [27]. When φDCMfurther increased from 30% (by volume) to 50% (by volume), the accelerating effect did not improve any more, probably due to that the solvent might already have enough polarity to affect the reaction. Another hand, the side reaction can also be accelerated by DCM, which was observed as that the increase of χA2is gradually fastened in the first 5 min with increasing φDCMin Fig. 3 (b). However, the χA2at the time ts(χA2s) reduces from 21.0% to 7.8% with increasing φDCMfrom 0 to 30%. These results can be explained as that the accelerated Eq. (1) increases the producing rate of C and the transformingrate of A, resulting the increase of Eq. (2) rate and the decrease of Eq. (2) amount. S in Exp. 0-4 is listed in Table 2 with corresponding t. It is found that S constantly decreases with increasing t, while the falling range of S reduces remarkably with increasing φDCM. The S at the time ts(Ss) increased from 65.3% to 91.2% with φDCMincreasing from 0 to 30%.

From the above results, it can be concluded that the bromination process with shorter ts, higher χA1sand higher Sscan be achieved by increasing φDCMfrom 0 to 30% (by volume). The bromination process with φDCMof more than 30% (by volume) is approximately same as that with φDCMof 30% (by volume), and thus φDCMof 30% (by volume) or more is suitable for the bromination. However, with the increase of φDCM, the density of the mixture solvent increases and is gradually close to the density of water, resulting in the increase of difficulty to separate water from the solution during the course of washing. Therefore, φDCMof 30% (by volume) is considered as the suitable DCM dosage.

3.3 Bromination processes of IIR in solvents with different assistant solvents

The bromination processes of IIR in solvents with different assistant solvents are contrastively shown in Fig. 4, which are the results of Exps. 0, 3, 5 and 6. To be consistent and comparable with Exp. 3, the ratio of Hex. to other assistant solvents is also set as 70% (by volume) to 30% (by volume). The adopted assistant solvents have different polarity as 0.06(Hex.)< 1.60(CTC)<3.40(DCM)<4.40(THMS). In Fig. 4, the variation trend of χA1and χA2with increasing t is same to that in Fig. 3. With the ratio of 70% (by volume) Hex. to 30% (by volume) assistant solvent, χA1sincreases, χA2sdecreases and tsreduced as the polarity of assistant solvent increased from 0.06 to 3.40. This indicates that the accelerating effect of assistant solvents on the bromination is closely related to their polarity. As the polarity of assistant solvent increases, polarity of the whole solvent increases, resulting in the enhancement of the accelerating effect of assistant solvent. However, the bromination carried out in 70% (by volume) Hex. + 30% (by volume) THMS is slightly slower than that in 70% (by volume) Hex. + 30% (by volume) DCM, probably due to a lower solubility of IIR in the solvent with 30% (by volume) THMS than that with 30% (by volume) DCM. Actually, acetone with polarity of 5.40 has been tentatively used as an assistant solvent to examine its effects on the bromination process, but the attempt was unsuccessful because IIR could not dissolve in the Hex. with 30% (by volume) acetone. These experimental results indicate that the polarity of solvent and solubility of IIR in the solvent are both important selection criteria of assistant solvents. S in Exp. 0, 3, 5 and 6 was also listed in Table 2 with the corresponding t. With comprehensive comparison of ts, χA1sand Ssin the bromination process in Exp. 0, 3, 5 and 6, DCM can be regarded as the optimum assistant solvent when the ratio of Hex. to assistant solvent is 70% to 30% (by volume).

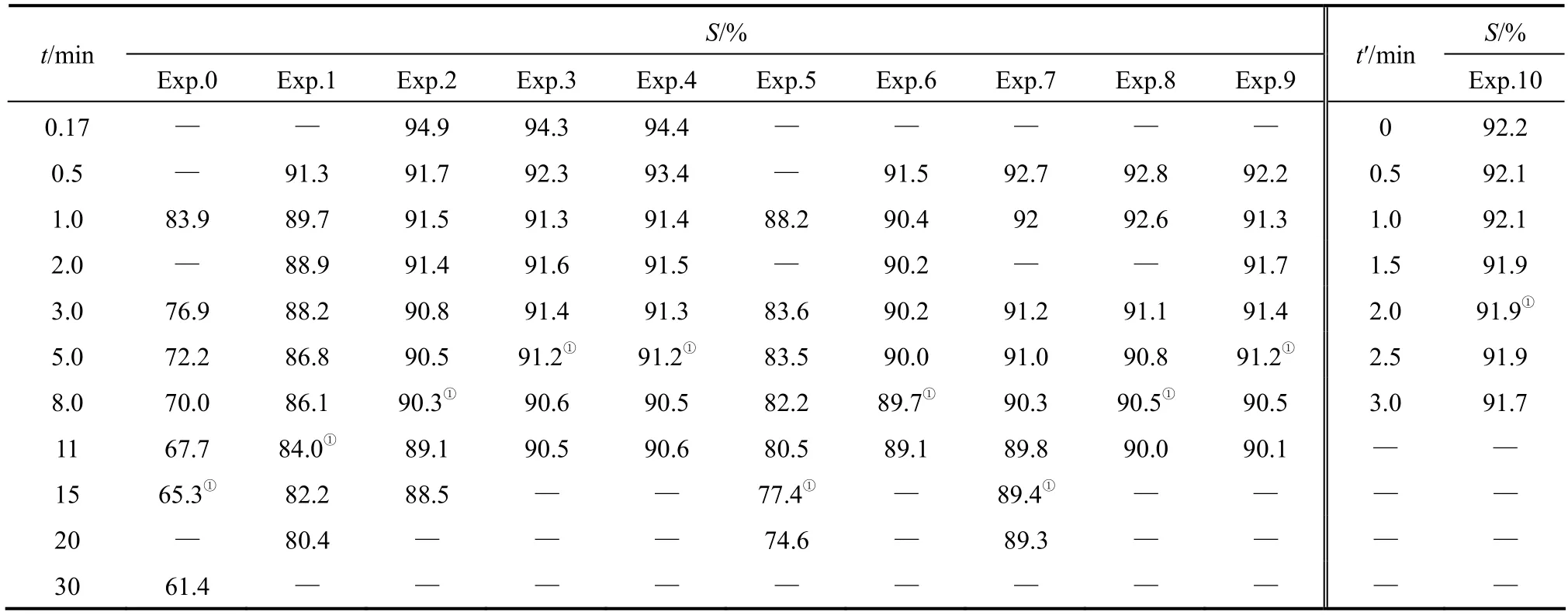

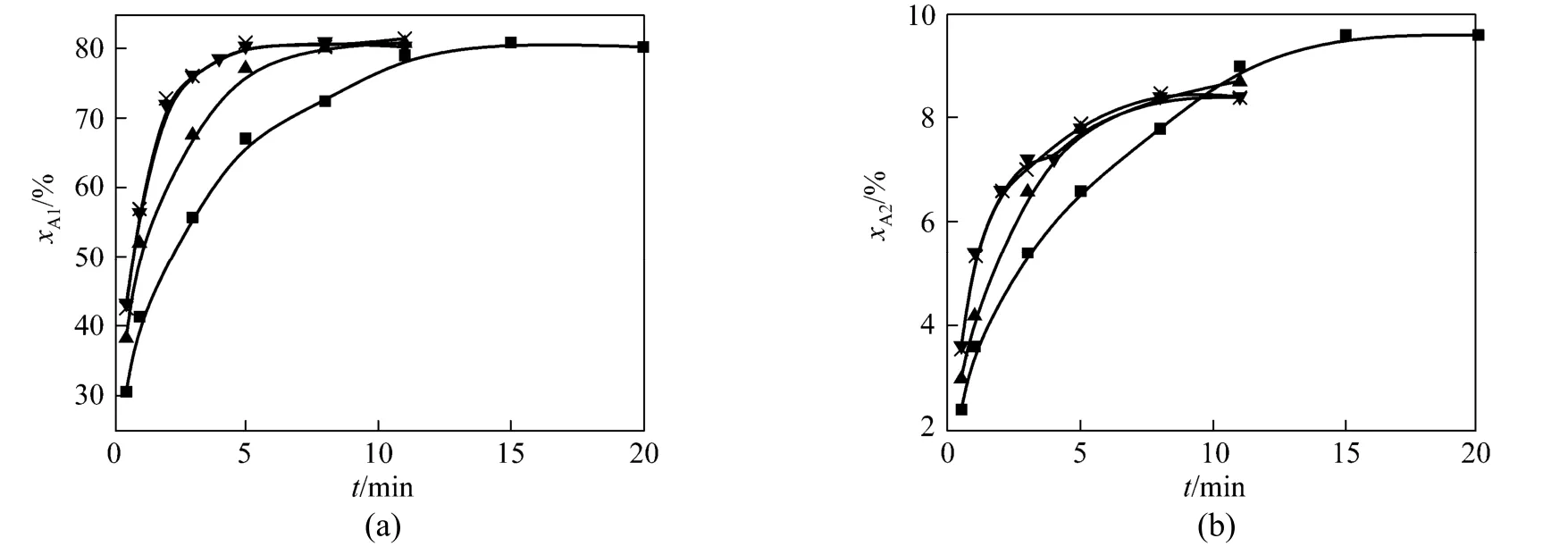

3.4 Bromination processes of IIR with different mixing conditions in STR

The variations of χA1and χA2with the increasing t, the results of Exp. 3 and 7-9, are shown in Fig. 5 as the bromination process of IIR with different mixing conditions in STR. It is observed that χA1and χA2both increase with time going until approach to a plateau. The tsreduces from 15 to 5 min with N increasing from 400 to 1100 r·min?1, while the χA1sremains stable and χA2sslightly decreases during this course. The experimental results with N of 1400 r·min?1are approximately same to that with N of 1100 r·min?1. The values of S in these experiments are also listed in Table 2. It is found that S slightly decreases with increasing t in Exp. 3 and 7-9. A slight increase of Ssfrom 89.4% to 91.2% is observed with increase of N from 400 to 1100 r·min?1. These results indicate that the apparent reaction rate of the bromination is observably affected by the mixing intensity. The effectsof mixing intensity on the main reaction and on the side reaction are concurrent, which results the similar Sswith different N. Even so, a high mixing intensity is necessary to achieve a high-efficiency bromination process and N of 1100 r·min?1can be determined as the optimal mixing condition in the 500 ml STR.

Figure 4 (a) xA1vs. t and (b) xA2vs. t with different assistant solventssolvent (by volume): ■ 70% Hex. + 30% Hex. (Exp. 0); ● 70% Hex. + 30% CTC (Exp. 5); ▼ 70% Hex. + 30% DCM (Exp. 3);★70% Hex. + 30% THMS (Exp. 6)

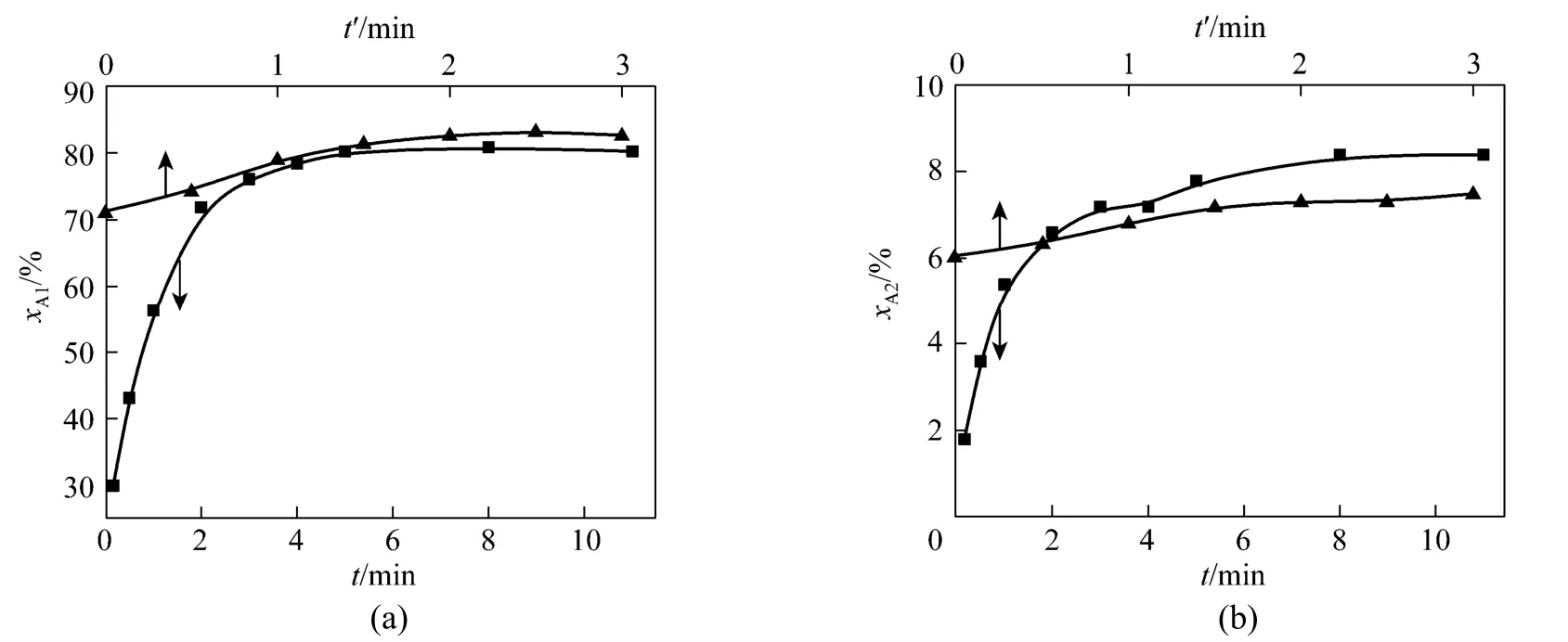

3.5 Bromination processes of IIR with different mixing conditions from different reactors

The bromination process of IIR with mixing in the RPB, which is carried out at parameters in Exp. 10, is shown in Fig. 6. The bromination process with mixing in the STR (Exp. 3) is contrastively shown in Fig. 6. These two sets of experiments are carried out with the same solvent, reactant concentration, temperature and rotating speed, but with the different reactor. The bromination in the STR is batch operation with processing capacity of 220 ml, while the bromination in the RPB is continuous operation with processing capacity of 550 ml·min?1. In Exp. 10, it is observed that χA1of 71.2% and χA2of 6.0% are obtained with t′ of 0, as a result of the bromination only in the RPB. With the increase of t′, χA1increases constantly till t′ of 2 min and χA2also has a slight increase. S in this experiment, which is listed in Table 2 with the corresponding t′, almost remain stable. With the comparison, it was obvious that the bromination process with mixing in the RPB is faster than that in the STR. The brominated result in Exp. 10 (χA1sof 82.6% and Ssof 91.9%) is better than that in Exp. 3 (χA1sof 80.2% and Ssof 91.2%). These results can be attributed to the different mixing conditions from the RPB and the STR. Although the rotating speed in the RPB (N=1100 r·min?1) is the same as that in the STR, the mixing intensity in RPB is higher than that in STR due to the excellent ability of RPB on dispersing liquids [18-20]. At t′=0, the value of χA1is 71.2%, playing as the main portion of the χA1s(82.6%). This indicates that RPB has played not only the role of mixing equipment but also the main role of bromination reactor, although t0is less than 1 s and is a negligible value in the total bromination time. Due to the advantages of RPB on mixing intensity and efficiency, the scale-up effect of RPB is non-significant [16-18], which is another superiority of RPB for the application of this reactor in the industrial bromination process of IIR.

Figure 5 (a) xA1vs. t and (b) xA2vs. t with different N in STRN/r·min?1: ■ 400 (Exp. 7); ◆ 800 (Exp. 8); ▼ 1100 (Exp. 3);1400 (Exp. 9)

Figure 6 (a) xA1vs. t or t′ and (b) xA2vs. t or t′ with different mixing conditions from different reactors■ mixing in the STR (Exp. 3); ▲ mixing in the RPB (Exp. 10)

4 CONCLUSIONS

On the basis of demonstrating the disadvantages of a slow bromination process of IIR, this work systemically investigated the effects of assistant solvents and mixing intensity on the bromination reaction process. It was found that higher dosage and polarity of assistant solvent were both beneficial to obtain faster bromination process with the premise of a nice solubility of IIR in the solvent. In STR, the significant effect of mixing intensity on the accelerated bromination process was observed as that tsreduced remarkably with increasing N. Hex. with 30% (by volume) DCM as assistant solvent and N of 1100 r·min?1were respectively found as the suitable solvent combination and mixing intensity in the STR, where χA1sof 80.2% and Ssof 91.2% could be obtained in 5 min. In a RPB with higher-intensity and higher-efficiency mixing than those in STR, χA1sof 82.6% and Ssof 91.9% could be obtained in 2 min. The usage of assistant solvent and RPB reactor can be concluded as a promising approach to intensify the industrial bromination process of IIR.

NOMENCLATURE

Aχintegral area of the characteristic peak with chemical shift χ in1H-NMR spectra of the samples

cA0initial concentration of A in reactor, mmol·L?1

cB0initial concentration of B in reactor, mmol·L?1

cNaClOinitial concentration of NaClO in reactor, mmol·L?1

N rotating speed of the mechanical stirrer in STR or the rotator in RPB, r·min?1

S selectivity of target-product P, %

Ssthe value of S with t of ts, %

t total bromination reaction time, min

tsthe reaction time value when χA1approached to a stable value, min

t0bromination reaction time in RPB, s

t′ bromination reaction time in the brown beaker, min

XAcontent (by mole) of A in the brominated samples, %

XA0content (by mole) of A in the IIR=1.67, %

XBrcontent (by mole) of bromine with the EXO and rearranged EXO structure, %

χAconversion of A, %

χA1conversion of A transferring via the main reaction, %

χA2conversion of A transferring via the side reaction, %

χA1sstable value of χA1, %

χA2sstable value of χA2, %

φDCMvolume content of DCM in the solvent, %

Subscripts

A 1,4-isoprene unit

B Br2

s stable value

χ chemical shifts of the characteristic peaks in 1H-NMR spectra of the samples

REFERENCES

1 Storey, R.F., Lee, Y., “Sulfonation of tert-alkyl chlorides: Application to the tert-chloride-terminated polyisobutylene system”, J. Polym. Sci. Part A: Polym. Chem., 29 (3), 317-325 (1991).

2 Chu, C.Y., Vukov, R., “Determination of the structure of butyl rubber by NMR spectroscopy”, Macromolecules, 18 (7), 1423-1430 (1985).

3 Gardner, I.J., Fusco, J.V., Newman, I.F., Kowalski, R.C., Davis, W.M., Baldwin, F.P., “Halogenated butyl rubber”, U.S. Pat., 4632963 (1986).

4 Sumner, A., Kelbch, S., Verbiest, A., “Halogenated butyl rubbers having a low halogen content”, U.S. Pat., 5886106 (1999).

5 Shan, B.T., “Preparation of bromobutyl rubber and characterization of its structure and property”, Master Thesis, Beijing Univ. of Chem. Tech., Beijing (2010). (in Chinese)

6 Baade, W., Konigshofen, H., Kaszas, G., “Process for the bromination of alkyl rubbers”, U.S. Pat., 5569723 (1996).

7 Liang, X.Y., Application Technology of Butyl Rubber, Chemical Industry Press, Beijing (2004). (in Chinese)

8 Parker, P.T., Baton, R.L., John, L., Bryan, J., “Continuous chlorination and bromination of butyl rubber”, U.S. Pat., 3099644 (1963).

9 Kowalski, R.C., Davis, W.M., Newman, N.F., Foroulis, Z.A., Baldwin, F.P., “Extrusion process for preparing improved brominated butyl rubber”, U.S. Pat., 4563506 (1986).

10 Kaszas, G., “Bromination of butyl rubber in the presence of electrophilic solvents and oxidizing agents”, Rubber Chem. Technol., 73 (2), 356-365 (2000).

11 Irving, K., Roselle, P., Francis, P., Robert, M.T., George, E.S., Roselle, N.J., “Nitrogen cured halogenated butyl rubber compositions”, U.S. Pat., 3104235 (1963).

12 Kenneth, W.P., Berkeley, H., Hsien, C.W., “Halogenation of star-branched butyl rubber with improved neutralization”, U.S. Pat., 5286804 (1994).

13 Delmer, L.C., Highland Park, N.J., “Halogenation of low unsaturation rubbery polymers in the presence of oxidizing agent”, U.S. Pat., 3018275 (1962).

14 Kaszas, G., “Kinetics and mechanism of the bromination of butyl rubber”, Polym. Prepr. (Am. Chem. Soc., Div. Polym. Chem.), 40, 579-580 (1999).

15 Yang, H.J., Chu, G.W., Zhang, J.W., Shen, Z.G., Chen, J.F., “Micromixing efficiency in a rotating packed bed: Experiments and simulation”, Ind. Eng. Chem. Res., 44 (20), 7730-7737 (2005).

16 Chen, J.F., Zheng, C., Chen, G.T., “Interaction of macro- and micromixing on particle size distribution in reactive precipitation”, Chem. Eng. Sci., 51 (10), 1957-1966 (1996).

17 Chen, J.F., Gao, H., Zou, H.K., Chu, G.W., Zhang, L., Shao, L., Xiang, Y., Wu, Y.X., “Cationic polymerization in rotating packed bed reactor: experimental and modeling”, AIChE J., 56 (4), 1053-1062 (2010).

18 Chen, J.F., High Gravity Technology and Application—A New Generation of Reaction And Separation Technology, Chemical Industry Press, Beijing (2003). (in Chinese)

19 Yang, H.J., Chu, G.W., Xiang, Y., Chen, J.F., “Characterization of micromixing efficiency in rotating packed beds by chemical methods”, Chem. Eng. J., 121 (2), 147-152 (2006).

20 Yang, K., Chu, G.W., Shao, L., Luo, Y., Chen, J.F., “Micromixing efficiency of rotating packed bed with premixed liquid distributor”, Chem. Eng. J., 153 (1), 222-226 (2009).

21 Li, W.Y., Wu, W., Zou, H.K., Chu, G.W., Shao, L., Chen, J.F.,“Process intensification of VOC removal from high viscous media by rotating packed bed”, Chin. J. Chem. Eng., 17 (3), 389-393 (2009).

22 Li, W.Y., Wu, W., Zou, H.K., Chu, G.W., Shao, L., Chen, J.F., “A mass transfer model for devolatilization of highly viscous media in rotating packed bed”, Chin. J. Chem. Eng., 18 (2), 194-201 (2010).

23 Xiang, Y., Wen, L.X., Chu, G.W., Shao, L., Xiao, G.T., Chen, J.F.,“Modeling of the precipitation process in a rotating packed bed and its experimental validation”, Chin. J. Chem. Eng., 18 (2), 249-257 (2010).

24 Zhang, L.L., Wang, J.X., Sun, Q., Zeng, X.F., Chen, J.F., “Removal of nitric oxide in rotating packed bed by ferrous chelate solution”, Chem. Eng. J., 181, 624-629 (2012).

25 Cheng, D.M., Gardner, I.J., Wang, H.C., Frederick, C.B., Dekmezian, A.H., Hous, P., “Spectroscopic studies of the structures of butyl and bromobutyl rubbers”, Rubber Chem. Technol., 63 (2), 265-275 (1990).

26 Chu, C.Y., Watson, K.N., Vukov, R., “Determination of the structure of chlorobutyl and bromobutyl rubber by NMR spectroscopy”, Rubber Chem. Technol., 60 (4), 636-646 (1987).

27 Smith, M.B., March’s Advanced Organic Chemistry: Reactions, Mechanisms, And Structure, John and Wiley Sons, Inc., New Jersey (2013).

2013-07-10, accepted 2013-12-19.

Chinese Journal of Chemical Engineering2014年4期

Chinese Journal of Chemical Engineering2014年4期

- Chinese Journal of Chemical Engineering的其它文章

- An Approach to Formulation of FNLP with Complex Piecewise Linear Membership Functions

- Determination and Correlation of Solubility for D-Xylose in Volatile Fatty Acid Solvents*

- Impacts of Power Density on Heavy Metal Release During Ultrasonic Sludge Treatment Process*

- One Step Preparation of Sulfonated Solid Catalyst and Its Effect in Esterification Reaction*

- Support Effects on Thiophene Hydrodesulfurization over Co-Mo-Ni/Al2O3and Co-Mo-Ni/TiO2-Al2O3Catalysts*

- Determination and Correlation of Solubilities of Four Novel Benzothiazolium Ionic Liquids with6PF?in Six Alcohols*