Modeling and optimization for oil well production scheduling☆

Jin Lang*,Jiao Zhao

1The Institute of Industrial Engineering and Logistics Optimization,Northeastern University,Shenyang,110819,China

2State Key Laboratory of Synthetical Automation for Process Industries,Northeastern University,Shenyang 110819,China

3School of Automobile,Chang'an University,Xi'an 710064,China

1.Introduction

Oil plays a major role in nowadays society because it covers the high demand for vehicle fuel and is widely used in industrial processing.In the middle and later periods of the oil field exploitation,oil reserves are finite and most oil fields will run in low-yielding and inefficient pumping.According to the statistics,there are about 80%light load oil wells among all the pumping oil wells.In the oil field exploitation,electricity consumption accounts for about 35%of the whole petroleum recovery cost.When oil well is running in light load state,a great deal of electric power will be wasted and original pressure equilibrium will seriously be destroyed. Compared to continuous pumping, the intermittent production method is more effective to tackle the issue of electricity waste in the oil field.It is possible to enhance oil field's productivity,increase operation life of oil well,and reduce production cost by effective pumping dispatch.In consideration of the actual production technique constraints,the oil well production scheduling problem in this paper is to determine the turn on/off status in each time period so that the total production operation cost of oil wells is minimized.

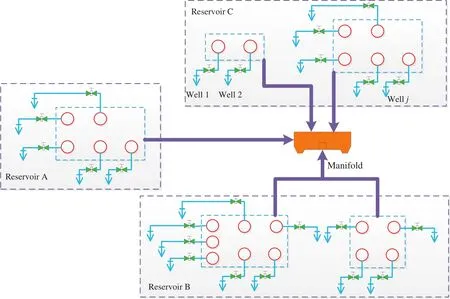

Oil fields are characterized by a large number of wells which spread over a wide geographical area.The wells normally share surface equipment and interconnect with each other through comprehensive pipeline networks as illustrated in Fig.1.Oil fields contain a lot of reservoirs,each of which contains many wells.The pressure of interconnected wells that belongs to the same reservoir decreases globally.Therefore,the wells which interconnect with each other in the same reservoir can be grouped into one batch.The novel operational approach proposed accordingly is to schedule the oil wells in batching.

Fig.1.Illustration of pipeline network of oil well in the oil field.

Compared with the conventional well scheduling problem, the problem in this paper has the following characteristics that make it difficult to be modeled and solved:(1)the problem contains both the discrete variables to determine the oil well turn on/off status, and the continuous variables to determine the oil production of oil wells;(2)during the oil production,not only minimum up and down time constraints,but also the mutual influence relations between the pressure of oil well bottom and oil production should be considered.These requirements and constraints further increase the problem difficulties,resulting in a very complex NP-hard problem.Since the number of wells scheduled in actual production is very large,it is impossible or very difficult to obtain an optimal solution of the problem in a finite time.Thus,proposing approximation algorithms become a natural choice.Many solution techniques were proposed focusing on the large scale practical production scheduling problems in the previous literature[1,2].In particular,in the area of oil production,Ortiz-Gomez et al.[3]studied the three mixed integer multiperiod optimization models in chemical industry.The problem took into account a fixed topology which was concerned with the decisions involving the start-up/shut-down of the operation of the process in each period of time.The models considered the nonlinear behavior of the well flowing pressure.Carvalho et al.[4]studied the oil well platform layout and the oil well distribution in each platform scheduling problem in sea,and proposed a mixed integer linear programming model.Iyer et al.[5]researched the scheduling problems for reservoir production offshore fields,and proposed a mixed integer nonlinear programming model,which considered a lot of economic indicators,and then presented a continuous decomposition technique to solve it.Kosmidis[6]researched the oil field wells' daily scheduling problems,taking into account the nonlinear characteristics of the reservoir,reservoir constraint multiphase flow and surface facilities,and established a mixed integer programming model to determine the switching state of the oil wells.Bohannon et al.[7]studied the oil field plans and production design integrated problem,and established a mixed integer programming model.In summary,existing studies only considered the needs of reservoir oil production and oil field reserve constraints,neither of them considered the stability requirements of well production and operation characteristics,nor the relationship belong to an oil reservoir and oil well's frequent turn on/off status on the well's own life and productivity.Bieker et al.[8]described how operational decisions were made based on weekly or monthly oil production plans,determining the optimal oil production at each well,and corresponding adjustments of controlling the pressure.Gunnerud and Foss[9]present a model formulation including manifolds,wells,pipelines and routing decisions for multiphase petroleum production asset.A piecewise linear approximation and decomposition approach was used to solve the problem.Ulstein et al.[10]used a network flow formulation to describe the main production and transportation process of multicomponent flows to satisfy market demand.Güyagüler and Byer[11]design an optimization procedure that used an MILP to model a petroleum production allocation problem.

Compared with previous related research,the oil well production scheduling problem in this paper considers the minimum up and down time constraints.This paper establishes a mixed-integer nonlinear programming model for the oil well production scheduling problem considering pressure and minimum up and down constraints.The goal is to minimize the oil well operation cost and the start-up costs.Thereafter,an improved PSO is constructed to solve the problem.In order to verify the effectiveness of the proposed PSO,computational experiment is carried out by comparing with Lagrange relaxation,binary particle swarm algorithm(BPSO)and the commercial solver CPLEX.

2.Problem Description and Model

2.1.Problem description

This work considers the short term planning of the oil production in the wells that belongs to the same reservoir over a time horizon T.Hence,given an oil field,there are n wells within the reservoir and the oil wells which interconnected with each other in the same reservoir can be grouped into a batch(block).The scheduling of oil wells in oil field production is to determine the optimum operation scheduling of oil well during a given planning horizon,which includes the decisions of determining the turn on/off time in each time period and the yield of production,so that the total production operation cost of oil wells is minimized while satisfying the demand of oil recovery and considering the impact of oil well's bottom pressure variation on its turn on/off status,minimum start up and shut down time and so on.

2.2.Mathematical model

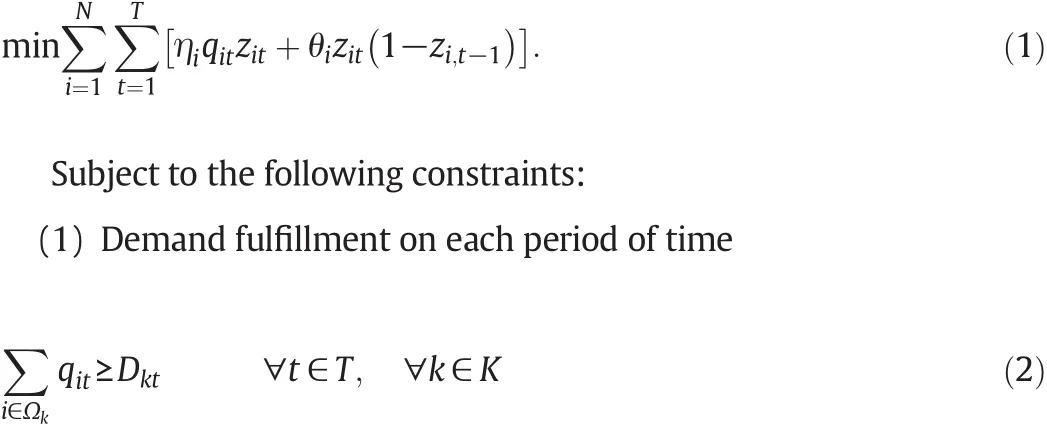

The problem can be formulated as a mixed integer optimization problem in which the objective function is to minimize the total operating costs over the scheduling horizon while satisfying all the constraints.The objective function includes production operation costs and start-up costs.Mathematically,the function is given as follows:

According to the above analysis,the formulation is a large-scale mixed integer programming with both continuous and integer decision variables.

3.PSO Algorithm

This paper proposed an improved particle swarm algorithm to solve an oil well production scheduling problem for the oil field exploitation.Particle Swarm Optimization(PSO)was first presented by Eberhart and Kennedy[12,13],and used to optimize the continuous nonlinear functions.Liao et al.[14]successfully applied PSO algorithm to solve a discrete optimization problem.

3.1.Particle encoding mode

This paper uses continuous PSO optimization algorithm directly to solve the oil well production scheduling problem,which means that the discrete variables are relaxed to continuous space.In this paper,the discrete variables are first mapped in the interval[0,10]within randomly-generated real number of primary particles,and then decoded to turning-on/off status of discrete oil wells.Particle with N oil wells and T cycles can be expressed as follows:

where S denotes the particles in the swarm and Sitis any one value between[0,10].The particles are encoding in real number value,which need to be transformed to turning on/off status of oil wells.The decoding process is as follows:

The parameters in PSO are set as follows:the inertia weight is obtained by formula(6).vmaxis set as 1,c1=2,c2=2.The initial velocity of each particle is set to 0,while the size of the swarm is 100.

On/off status of oil well obtained by these two methods is random,thereby making most of the particles unable to satisfy the oil well combination constraints.This paper presents an initial population repair strategy to ensure that the particles in the swarm meet the minimum up and down time constraints,and improve the solution quality.Priority list method is used for determine the turn on/off status of oil well.The characteristic curve of oil well consumption is E=γi× xit.Obviously,the larger the oil well coefficient γi,the lower the efficiency of the oil well will be.Therefore,the ascending orders for the oil well are employed to give priority for the oil well starting and stopping order.The fitness function of particle swarm optimization is calculated directly using the objective function of oil well scheduling problem.If the fitness value is smaller,then the objective function value of the particle is smaller which means that the particle is more excellent.

3.2.An improved PSO

As the size of the problem in practical scheduling is often large,and also due to the complexity of the problem itself,the PSO algorithm falls into local optimal easily.On account of this,an improved PSO algorithm(IPSO)is presented,in which a new velocity updating formula is proposed to improve the performance of the PSO algorithm.The new velocity updating formula is listed as follows:

where m and n denote the m-th and the n-th units in the particle,respectively,k represents the iteration of the algorithm and itself,ξ,η,ψ∈U[0,1]are random numbers in the interval.

3.3.Repair turn on/off status

The turn on/off status are repaired to meet the minimum up and down time constraints.The continuous turning on timeand turning off timein time period of each oil well should be obtained before repairing is made.The calculating formulas are as follows:

Eq.(17)indicates that the maximum production output of all the oil wells at time t should satisfy the demand constraints.The repair of detailed process is as follows:

Supposethe illustration of repair oil well turn on/off status is shown in Fig.2.

Fig.2.Repair turns on/off status.

3.4.Constructing a feasible solution

Heuristic and priority list methods are combined to construct feasible solutions.Except for local adjustment strategy and repairing minimum up and down time constraints,the determination of the production output of the oil wells also needs to meet the maximum and minimum production output constraints of the oil well starting conditions,and therefore it is necessary to determine oil well production output.As the turn on/off status of the oil well will affect the status and production output in the following-up time periods,the turn on/off status should be re-adjusted and oil well production output of the oil well at this period needs to be determined so as to meet all the constraints and obtain a feasible solution.The adjustment idea is illustrated as follows:

Step 1:Take the schedule obtained from the turn on/off status as an initial schedule.Letis the surplus value of demand at t

In order to satisfy the demand of system,the oil wells whose pressure can ensure production should be turned on.The well can be turned on in three cases:

Supposeat time t=6,the pressure of oil well i1is insufficient.Thus,the oil well is forced to shut-down.Fig.3 shows the changes of turn on/off status.

Fig.3.Turn off operation in case of insufficient pressure.

Shut-down oil well i1may cause the oil well scheduling system to dissatisfy the demand of the system.Therefore,another oil well i2should be turned on.

(1)Turn on the oil well that meets the minimum off time,as shown in Fig.4.

Fig.4.First case of oil well turns on.

(2)Turn on the oil well that is on in the previous time period,as shown in Fig.5.

Fig.5.Second case of oil well turns on.

(3)If the previous cases are not applicable, fi nd an oil well that does not meet the minimum off time and back forward to time period when it is turned on.Then,turn on the oil well,as shown in Fig.6.

Fig.6.Third case of oil well turns on.

3.5.IPSO procedure

By the above heuristic,we can obtain the turn on/off status and oil production of oil wells that meet all the constraints.Thus,the fitness value of particles can be determined.These are the steps of IPSO.

The steps of IPSO to solve the oil well scheduling problem are as follows:

Step 1:Randomly generates a population with population size M.The value of each individual is in[0,10]real number matrix and the scale is N×T,k=1.

Step 2:Eq.(8)is decoded into a particle turn on/off status to satisfy Eq.(3).A portion of the particles is adjusted according to the priority order to get a better on/off status order.

Step 3:Determine the qitby heuristic rules of above introduction.

Step 4:Get the fitness value of each particle.If the fitness of the new particle is better than the local optimal valuethen update theusing the fitness value of this new particle.Ifis better than the global optimal valuethen update the value ofusing the value of

Step 5:Using Eqs.(14)and(12)to update the particle velocity.

Step6:According to Eq.(11)to change the position of the individual,out of range of the particles is processed using Eq.(13),and re-encoded and mapped into turn on/off status by Eq.(8).

Step 7:If k<K,k=k+1,go to Step 2,otherwise go to Step 8.

Step 8:Stop.

4.Results and Analysis

4.1.Experimental parameter settings

The algorithms are coded with C++programming language and implemented in the development environment of Visual Studio 2005.All the computational experiments are performed on a computer with Intel Core i5 3.1 GHz CPU and 4 G RAM.

Supposing the scheduling horizon is 24 h,the experimental data are randomly generated according to practical production data.The minimum and maximum oil productions of oil well follow uniformed distributions which satisfy corresponding at interval between 30 and 100 and the interval between 800 and 1200,respectively.The minimum shut on and off time is uniformed distribution which satisfies interval between 1 and 6.The experiments are tested using 10 sizes with each size of 10 sets of data.The data in the table is the average value of 10 set of data for each size.The running time of CPLEX is 100 s.

4.2.Lagrangian relaxation method

In order to evaluate the performance of the IPSO algorithm,the Lagrangian relaxation algorithm is applied to obtain a lower bound as well as a feasible solution of the primal problem.The demand coupling constraints are relaxed and embedded as a penalty term multiplied by Lagrangian multipliers in the objective function,leading to a relaxed version of the primal problem,which can be decomposed into several independent subproblems easier to solve.Here,Lagrangian multiplier{λkt}is associated with Eq.(2).Thus,the Lagrangian problem is formulated as follows:

subject to Eqs.(3)–(7).

Based on the duality theory,the LR method tries to maximize the dual objective function.The Lagrangian dual problem is

(LD):Max L(λ)with

The results obtained by the relaxed problem are usually not feasible to the original problem.Thus,a heuristic method is used to generate a good feasible solution based on the results of relaxed problem.Because non-aftereffect property of dynamic programming is not satisfied,CPLEX is used to solve subproblem.The difference in value between the solution for the primal problem and the optimum solution for the dual problem yields the duality gap.The relative duality,gap σ=(Z–L*)/L*,is selected as the performance of the algorithm.σ=0.5 is chosen in this paper.The value of the dual function L*provides a LR lower bound for the primal problem.A detailed description of the general LR method can be found[17].

4.3.Comparison of experiment results

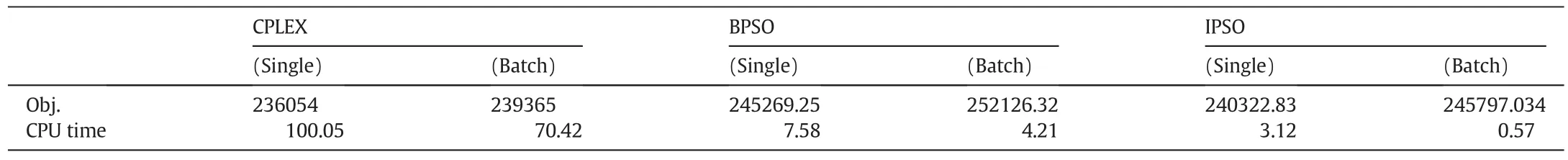

In order to verify the effectiveness of the proposed IPSO algorithm,different tests are designed to evaluate the running time and objective function value of the algorithm.(1)CPLEX.(2)LR algorithm.(3)Binary particle swarm algorithm,marked as BPSO.The results are shown in Tables 1 and 2.The numerical value in Table 2 is the ratio that is:ARi=Zi/min{Z1,Z2,Z3,…,Z6},(i=1,2,3,…,6),where Z1/Z2expresses objective function value of CPLEX obtained in solving the single model and batch model,Z3/Z4expresses the basic objective function value ofBPSO obtained in solving the single model and batch model and Z5/Z6expresses the objective function value of IPSO obtained in solving the single model and batch model.

Table 1 Computational result of the proposed model and algorithm

Table 2 Computational time of the proposed model and algorithm

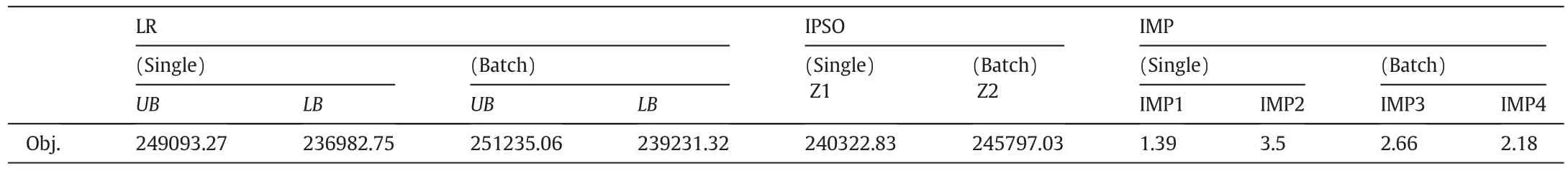

Table 3 Comparison of results for LR and IPSO

From the results in Tables 1 and 2,the following conclusions can be obtained:

(1)For the small-scale problems,the objective value obtained by IPSO was close to that obtained by CPLEX.

(2)For the medium-and large-scale problems,CPLEX was not able to obtain the optimal solutions within the setting time(100 s)for single model.The designed IPSO can quickly get the solution of problems regardless of single model.

(3)Comparing the proposed IPSO to CPLEX, the solution obtained by CPLEX was not better than that obtained by IPSO in solving large scale problems. The deviation between the objective values of both solutions was only 0.49%, but the efficiency of IPSO for solving the problems was 56.41 times of CPLEX.

(4)Comparing the proposed IPSO to BPSO,the objective function value of IPSO was obviously better than BPSO.Compared with BPSO,the quality of the solution based on the batch model was improved by 5.5%and the efficiency of solution was improved by 1.64 times.

The comparison results of IPSO with LR in terms of the upper bound(UB)and lower bound(LB)are shown in Table 3.For the single model,de fine IMP1=100×(UB?ZIPSO)/UB and IMP2=100×(ZIPSO?LB)/ZIPSO.The results indicate that the average deviation between the objective value obtained by IPSO and LR upper bound is 1%,and the average deviation with LR lower bound is 3.84%.For the batch model,define IMP3=100×(UB?Z)/UB and IMP2=100×(Z?LB)/Z.The results show that the average deviation between the objective values obtained by IPSO and LR upper bound is 0.95%,and the average deviation with LR lower bound is 3.93%.From the results obtained,it is observed that the proposed IPSO algorithm can obtain better solutions compared with the LR algorithm.

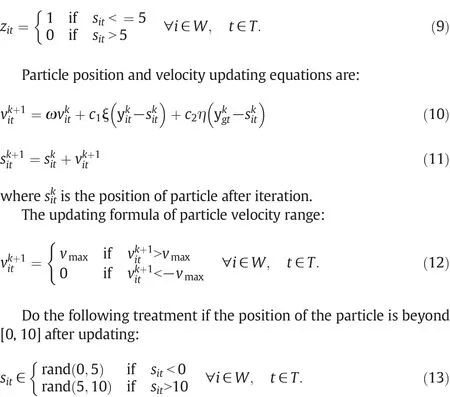

Figs.7 and8 show show that the efficiency of proposed model is obviously better than the single-machine model.The proposed IPSO has higher precision,which is obviously better than the other algorithms on computational time.

Fig.7.Comparison of computational results for each model and algorithm.

4.4.Tests on real-world data

To generate representative problem instances,the actual production data from Daqing oil field of CNPC were examined.Actual verification was carried out on practical data from southern experimental area of Sabei Development Zone,which covers an area of 4.22 km2.The initial pressure in this area was 11.90 MPa,while the saturation pressure was 11.0 MPa.It owned 67 production wells,with well spacing density of 26.6 km2.Supposing the scheduling horizon was 24 h, the calculation results are shown in Tables 4–6 below:

The test results on actual production data show that in the aspect of modeling the proposed model is superior to single-machine model on the searching speed of solution.In terms of optimization,the proposed ipso method is superior to other algorithms not only on precision,but also on solution time.

Fig.8.Comparison of computational time.

Table 4 Computational results of the proposed model and algorithm

Table 5 Computational results of the LR and IPSO

Table 6 Comparison of computational time

5.Conclusions

This paper focused on the oil well scheduling problem in the practical oil field production.The practical production constraints,such as the well group's demand for oil production,the restrained pressure in the oil well bottom and minimum up and down constraints were taken into consideration.A nonlinear mixed-integer programing model was established for the problem which aimed to minimize the cost of oil production and start-up cost.An improved PSO algorithm was designed to solve the problem.The algorithm was operated by mapping discrete variable to the continuous relaxation space,changing coded scheme into real coding,and then carrying out the experimental analysis for the selection of continuous space and velocity range by decoding turn on/off status.Besides,a new velocity updating formula was proposed to improve the performance of the IPSO algorithm.The performance of the proposed IPSO were compared with LR,BPSO and the commercial solver CPLEX by the experiment results of randomly generated instances,which demonstrated that the proposed improvement strategies were effective for PSO algorithm.

[1]L.X.Tang,G.S.Wang,Z.L.Chen,Integrated charge batching and casting width selection at Baosteel,Oper.Res.62(4)(2014)772–787.

[2]L.X.Tang,Y.Zhao,J.Y.Liu,An improved differential evolution algorithm for practical dynamic scheduling in steelmaking-continuous casting production,IEEE Trans.Evol.Comput.18(2)(2014)209–225.

[3]A.Ortiz-Gomez,V.Rico-Ramirez,S.Hernandez-Castro,Mixed-integer multiperiod model for the planning of oil field production,Comput.Chem.Eng.26(4–5)(2002)703–714.

[4]M.C.A.Carvalho,J.M.Pinto,A bi-level decomposition technique for the optimal planning of offshore platforms,Braz.J.Chem.Eng.23(2006)1–11.

[5]R.R.Iyer,I.E.Grossmann,S.Vasantharajan,A.S.Cullick,Optimal planning and scheduling of offshore oil field infrastructure investment and operations,Ind.Eng.Chem.Res.37(1998)1380–1397.

[6]V.D.Kosmidis,J.D.Perkins,E.N.Pistikopoulos,A mixed integer optimization formulation for the well scheduling problem on petroleum fields,Comput.Chem.Eng.29(7)(2005)1523–1541.

[7]M.J.Bohannon,A linear programming model for optimum development of multi-reservoir pipeline systems,J.Pet.Technol.22(11)(1970)1429–1436.

[8]H.Bieker,O.Slupphaug,T.Johansen,Real-time production optimization of shore oil and gas production systems:a technology survey,SPE Prod.Oper.22(2007).

[9]V.Gunnerud,B.Foss,Oil production optimization—a piecewise linear model,solved with two decomposition strategies,Comput.Chem.Eng.34(2010)1803–1812.

[10]N.Ulstein,B.Nygreen,J.Sagli,Tactical planning of offshore petroleum production,Eur.J.Oper.Res.176(2005).

[11]B.Güyagüler,T.Byer,A new rate-allocation-optimization framework,SPE Prod.Oper.23(2008)448–457.

[12]R.C.Eberhart,J.Kennedy,A new optimizer using particle swarm theory,Proceeding of 6th international symposium on Micromachine and Human Science,Nagoya,Japan 1995,pp.39–43.

[13]J.Kennedy,R.C.Eberhart,Particle swarm optimization,Proceeding IEEE international conference neural networks 1995,pp.1942–1948.

[14]C.J.Liao,C.T.Tseng,P.Luarn,A discrete version of particle swarm optimization for flow shop scheduling problems,Comput.Oper.Res.34(2007)3099–3111.

[15]J.F.Shapiro,Generalized Lagrange multipliers in integer programming,Oper.Res.19(1971)68–76.

[16]M.L.Fisher,The Lagrange relaxation method for solving integer programming problems,Manag.Sci.27(1981)1–18.

[17]J.E.Beasley,Lagrangian relaxation,in:C.R.Reeves(Ed.),Modern heuristic techniques for combinatorial problems,Blackwell Scientific,Oxford 1993,pp.243–303.

Chinese Journal of Chemical Engineering2016年10期

Chinese Journal of Chemical Engineering2016年10期

- Chinese Journal of Chemical Engineering的其它文章

- CFD modeling of a headbox with injecting dilution water in a central step diffusion tube☆

- Interactions between two in-line drops rising in pure glycerin☆

- Hydrodynamics of three-phase fluidization of homogeneous ternary mixture in a conical conduit—Experimental and statistical analysis

- Adsorption of Hg(II)from aqueous solution using thiourea functionalized chelating fiber☆

- Nickel(II)removal from water using silica-based hybrid adsorbents:Fabrication and adsorption kinetics☆

- Reactive dividing wall column for hydrolysis of methyl acetate:Design and control☆