Isobaric vapor–liquid equilibrium for binary system of aniline+methyl-N-phenyl carbamate☆

Yuqian Li,Liguo Wang,Peng He,Kelin Huang*,Huiquan Li,Yan Cao,*

1Chemistry and Material Science College,Guangxi Teacher Education University,Nanning 530001,China

2Key Laboratory of Green Process and Engineering,National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,Institute of Process Engineering,Chinese Academy of Sciences,Beijing 100190,China

3China Academy of Science&Technology Development,Guangxi Branch,Nanning,530022,China

1.Introduction

Diphenylmethane diisocyanate(MDI)is an important chemical precursor in polyurethane(PU)industry,which is widely used in the field of elastomer,elastic fiber,foamed plastic and so on.It is estimated that about 2.46 million MDI were produced in China in 2014[1],and it will increase year by year with the development of world economic.Traditionally,MDI was produced by phosgene method which is highly toxical and dangerous.What is more,the byproduct HCl causes serious equipment corrosion[2,3].Therefore,the non-phosgene process is getting more and more interested for the researchers since it is a relatively secure and green process.Among various reported non-phosgene processes,thermal decomposition of methylene diphenyl dicarbamate(MDC)to MDI is the most promising way,in which methyl n-phenyl carbamate(MPC),is an important precursor for MDC production[4].

Several processes of the MPC production are reported such as onepot synthesis and coupling route as illustrated in Fig.1[4–11].In these processes,aniline(An)is indispensable because it is the starting material for MPC production.Since it is difficult for An to attend 100%conversion,it is important to separate An with MPC effectively to obtain the high purity MPC after these reactions,and at the same time,realize the reusable of the unreacted An to balance its high price.

As it is known,the separation of the mixtures requires knowledge of the thermodynamic properties and the vapor–liquid equilibrium.However,to the best of our knowledge,these data is not previously reportedin the literature for the An and MPC binary system.What is more,Zhu et al.[12]studied the decomposition of MPC to phenyl isocyanate(PI)at high temperatures between 463.00 K and 513.00 K.Xu et al.[9]reported that the Antoine constants of A,B,and C of MPC are 17.87,6691.34 and?27.75,respectively.Some other basic thermodynamic properties of MPC and An are published in the Knovel database and Perry's Chemical Engineers' Handbook[13].

In summary,the isobaric vapor–liquid equilibrium data for binary system of An and MPC was very important to the purification of MPC.In this study,the quasi-static ebulliometric method,which is usually applied on binary system[14–16],is used in all measurements.The Antoine equation was used to fit the vapor pressure data of the purified MPC that were measured in this study.The T–p–x data for the MPC and An binary system at pressures of 2.00,4.00,6.00,7.00,and 8.00 kPa was measured.Finally,The NRTL and Wilson models were used to regress the experimental data[17].

2.Experimental Sections

2.1.Chemicals

Fig.1.The MPC production processes.

In this work,the chemicals used include:n-decane(CAS Registry No.124-18-5),mass fraction≥99.00%,from Tokyo Chemical Industry(Shanghai)Co.,Ltd.MPC(CAS Registry No.2603-10-3)was prepared from the reaction between dimethyl carbonate and diphenylurea as our previously reported[18];the purity of MPC is checked by HPLC,and no observable impurities were shown by the HPLC analysis.An(CAS Registry No.62-53-3)mass fraction≥99.98%,from Aladdin Industry Corporation(Shanghai)Co.,Ltd.Dimethyl carbonate(CAS Registry No.616-38-6)mass fraction≥99.00%,from Shandong Hi-tech Chemical Group Co.,Ltd.Diphenylurea(CAS Registry No.102-07-8)mass fraction≥99.50%,from Tokyo Chemical Industry(Shanghai)Co.,Ltd.Lead monoxide(CAS Registry No.1317-36-8)mass fraction≥99.50%,from Sinopharm Chemical Reagent Co.,Ltd.Cyclohexane(CAS Registry No.110-82-7)mass fraction≥99.00%,from Xilong Chemical Reagent Co.,Ltd.n-Butyl acetate(CAS Registry No.1123-86-4)mass fraction≥99.00%,from Sinopharm Chemical Reagent Co.,Ltd.

The water was purified by Milli-Q gradient synthesis.

2.2.Synthesis of MPC

MPCwas obtained by the reaction between diphenylurea(DPU)and dimethyl carbonate(DMC)using 1 wt.%–3 wt.%(based on DPU)PbO as catalyst.Firstly,the reactants DPU and DMC with the mole ratio of 1:1 were charged in 2 dm3batch pot.The mixture was then heated to 443.00 K and reacted for 3 h under mechanical stir.Subsequently,the unreacted DMC was separated by rotatory evaporator from the reactants to obtain crude MPC.Finally,the high purity MPC was obtained by recrystallization in cyclohexane more than once.

2.3.Thermogravimetric analysis of MPC

The thermogravimetric analysis(TGA)is carried out using a Discovery thermal analyzer(TA Group,America).10–20 mg of MPC is added to the platinum pan under a N2flow of 10 ml·min-1,at heating rates of 5 K ·min-1and interval of temperature of 25–250 °C.

2.4.Apparatus and Procedure

All-glass inclined ebulliometer was used in this study as shown in Fig.2.The apparatus consisted of an inclined ebulliometer,a set of dig-ital vacuum pressure controller with high accuracy and a vacuum pump(Edwards Vacuum).Two buffer vessels that are approximately 10 dm3are connected with the inclined ebulliometer.The admission valve was used to control the system pressure.The 1#condenser was cooled with a circulating ethanol(approximately 267 K)to minimize the most of condensed vapor because the evaporation of solvent would change the initial concentration of the samples in the experiment of measuring the T–p–x data.After the MPC vapor pressure was measured,the temperature of 1#condenser circulating water was then kept at 328.15 K.The temperature of 2#condenser was kept at 238.15 K.The system pressures were measured by the mercury manometer and Pirani vacuum gaugein case of it was more than and less than1.00kPa,respectively.The accuracy is 0.1 kPa for mercury manometer and 0.05 kPa for Pirani vacuum gauge,respectively.The equilibrium temperatures are measured by the mercury thermometer whose accuracy is 0.10 K which was within the limits of investigated temperature.The good performance of the equipment was con firmed in the previous experiment.

Fig.2.The All-glass inclined ebulliometer.1—heating element;2—magnetic stirrer;3—incline ebulliometer;4–1#condenser;5—mercury thermometer;6—mercury manometer;7—Pirani vacuum gauge;8—pressure gauge;9—needle valve;10—1#buffer vessel;11—2#buffer vessel;12—2#condenser;13-vacuum pump.

The VLE data of the samples were measured as follows.Firstly,the samples were melting at about 328.15 K,which were analyzed by HPLC,and charged into the inclined ebulliometer with approximately 85 cm3.The system pressures were adjusted to the desired pressures,and then the samples were heated and stirred vigorously with a magneticstirrer to stem super heating and get homogeneous mixing.A mixture of liquid and vapor were sprayed gradually to the thermometer sleeve.When the reading of the mercury thermometer was almost stable about 30 min,the vapor–liquid equilibria were established and meanwhile the temperature and pressure were recorded.

2.5.Verification of procedure

The experimental apparatus for VLE data measurement were verified by determining the vapor pressures of water and n-decane,respectively[9].And then,compare the experimental data with literature[13].Vapor pressure data of n-decane ranging from(1.98 to 12.97)kPa and water ranging from(2.07 to 10.56)kPa were measured,respectively.They are in good agreement as shown in Fig.3.The average absolute pressure deviation of the water and n-decane were 0.09 kPa and 0.45 kPa,respectively.In view of the above,it was considered to be reliable to measure the boiling points of samples with the new established apparatus and procedure from(1.98 to 12.97)kPa.

Fig.3.Comparison between the measured and published vapor pressures of water and ndecane.Symbols indicate experimental data in this work:Δ,water;□,n-decane;solid lines,literature.

The apparatus and procedure for VLE measurement were veri fi ed by measuring VLE data for the butyl acetate+cyclohexane binary mixture and comparing experimental data with literature data[16].The experimental results for the butyl acetate+cyclohexane at the pressures of(2.00,4.00 and 8.00)kPa were illustrated in Fig.4.The average absolute temperature deviation of the butyl acetate+cyclohexane were 0.12 K and the maximum absolute deviation of the butyl acetate+cyclohexane were 0.28 K.In view of the above,it was considered to be reliable to measure the boiling points of samples with the new established apparatus and procedure in this experiment system.

Fig.4.Isobaric VLE diagram for the butyl acetate(1)+cyclohexane(2)binary system at(2.00,4.00 and 8.00)kPa;□—2.00 kPa;○—4.00 kPa;△—8.00 kPa;—(T–x);---(T–y),NRTL equation.

3.Results and Discussion

3.1.Thermodynamic modeling

The Antoine equation as shown in Eq.(1)was fitted by the experimental data in this study.

where Ai,Biand Ciare the three parameters for the Antoine equation and were regressed with the experimental data in this work.

When the vapor–liquid phase equilibrium is established,it is known that the fugacity of the gas phase is equal to that of the liquid phase.Thus,the equilibrium expression can be described by Eq.(2)[19–22].where T and p are the equilibrium temperature and pressure,respectively;γiis the activity coefficient of component i;piSis the saturated vapor pressure of pure component i;respectively,yiand xiare the molar fraction of component i in the vapor phase and liquid phase.At low pressures(below 200 kPa,which is our case),vapor phases usually approximate ideal gases,for which.In this paper, the activity coefficient of component γiis calculated by NRTL model and Wilson model[23–25].

Fig.5.TG/DTG curves of sample MPC.

Table 1 Vapor pressure of the MPC①

In this study,the maximum-likelihood principle was used to regress the binary parameters and by Aspen plus software [16,24], the objective function is:

where f is weight factor,σ is standard deviation,x is the liquid phase composition.The superscript“exp”is the experimental data,while the“cal”is the calculated result.

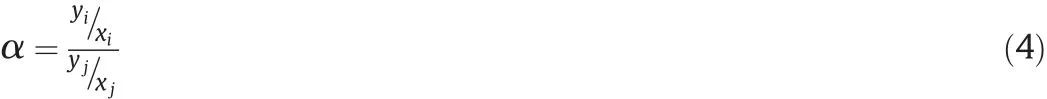

The relative volatility is de fined as Eq.(4):

where y and x are the mole fractions of the components in the vapor and liquid phase..

Table 2Antoine constants of MPC

The root-mean-square deviation(RMSD)is de fined as Eq.(5):

where N is the number of experiment pointsrepresents the calculated and the experimental value of the temperature and pressure,respectively[21].

The Herington integral test,based on the Gibbs–Duhem equation,is a semi empirical method and has been employed for examining the thermodynamic consistency of the experimental p–T–x data here[31].With the calculated activity coefficients,ln(γ1/γ2)has been found to be well fitted for each system by a third-order polynomial in x1on a plot of ln(γ1/γ2)versus x1.Let A+be the area above the ln(γ1/γ2)=0 line and underneath the curve.Also,A?represents the area underneath the ln(γ1/γ2)=0line and above the curve.From these plots, the parameter D for each system can be calculated as Eq.(6):

Table 3 VLE data for the An and MPC system at different pressures(below 393.19 K)①

According to the Herington method,D should be compared with another parameter J,as de fined below:

where Tmaxand Tminare the highest and lowest temperatures over the entire composition range for each system.If the consistency criterion|D?J|<10,the corresponding VLE data are considered to be thermodynamically consistent.

In this study,the T–p–x–y experimental data for the system is correlated by NRTL model and Wilson model[23,25,27,28]at(2.00,4.00,6.00,7.00 and 8.00)kPa.

3.2.Thermogravimetric analysis of MPC

Fig.5 shows the TG and DTG curves of the combustion of MPC solid at 5 K·min?1in N2atmosphere.As can be seen,the mass loss increases along with the temperature from 345.34 K to 451.21 K.The extrapolation onset decomposition temperature of MPC was 406.25 K.Thus,all the vapor–Liquid equilibria data were measured below 406.25 K to avoid the decomposition of MPC.

3.3.Vapor pressures of MPC

The vapor pressure data of MPC were measured first in the range from(0.19to0.65)kPa as shown in Table 1. The Antoine constants listed in Table 2, are regressed with the experimental T–p data of MPC with the overall average absolute pressures deviation of 0.01 kPa.The comparison between the measured and Antoine equation regressed data of MPC vapor pressure was shown in Fig.6.It is seems that the Antoine equations are able to describe the vapor pressures of the MPC well.The vapor pressures of MPC,ranging from 0.65 to 8.00 kPa,were calculated by using the extrapolation,because of its instability at more than 0.65 kPa.Therefore,the saturated vapor pressure of pure component calculated using the Antoine constants could be applied to the NRTL and Wilson models.

3.4.Vapor–liquid equilibria for the An and MPC system

The quasi-static ebulliometric method was also used to determine the T–p–x data of the An and MPC binary system at(2.00,4.00,6.00,7.00 and 8.00)kPa at liquid mole fraction of An ranging from(0.10 to 0.90).All the T–p–x data were determined below 389.54 K to avoid the decomposition of MPC[29].

The VLE data of the An and MPC system calculated from both of the NRTL and Wilson models using Aspen plus[24]were listed in Table 3 and the good regressed results of NRTL and Wilson models can be seen as shown in Fig.7.

Accordingly,the correlated binary interaction parameters of Wilson and NRTL models,are calculated from the VLEd at a and the results were shown in Table 4,together with the RMSD.The results show that the RMSDs in pressure and temperature for binary systems are less than 0.008 kPa and 0.65 K,respectively,which means both of the two correlation models are able to describe the VLE relationship of binary systems,without any Significant difference between them.Furthermore,A summary of the thermodynamic consistency test results were shown in Table 5.As can be seen,the T–p–x data reported in this paper have passed the thermodynamic consistency test.The average absolute deviations of pressure are0.01kPa for both of NRTL and Wilson model,while the average absolute deviations of temperature is 0.54 K for the NRTL model and 0.53 K for the Wilson model respectively.All the above results give the conclusion that both of NRTL and Wilson model can satisfactorily describe the VLE behavior of the binary system at(2.00,4.00,6.00,7.00 and 8.00)kPa.

Fig.7.VLE phase diagram of the An and MPC binary system at(2.00,4.00,6.00,7.00,and 8.00)kPa.The liquid mole fraction of An is the experimental data in this work:□—2.00 kPa;○—4.00 kPa;△—6.00 kPa;▽—7.00 kPa;?—8.00 kPa.Solid line,T–x curves predicted by the NRTL(a),and Wilson(b).

With the quasi-static ebulliometric method, the liquid phase properties could be used to calculate the vapor compositions because the liquid compositions xiis approximately equal to the feed compositions zi[27,28].Accordingly,the y1–x1data of the binary system of An and MPC were drawn in Fig.8.As shown in this figure,the azeotropic behavior is not found in the binary system.

Furthermore,in order to describe in detail the separation performance of the binary system at low pressure,the relative volatility(α)of the binary system of the An and MPC was studied and then listed in Fig.9.Synchronously,the NRTL model was used to calculate and predict the relative volatility(α)of the mixture.It was found that the relative volatility of MPC to An is far more bigger than 1 at the measured pressure range which has shown an agreement with the results of the y–x diagram.It also could be seen that the relative volatility is decreased quickly with the liquid mole compositions of An from 0 to 0.18 at(2.00,4.00,6.00,7.00 and 8.00)kPa and unchanged virtually from 0.18 to 1.00 at(4.00,6.00,7.00 and 8.00)kPa,but increased rapidly at 2.00 kPa.The separation effect of the system of An and MPC can be ascribed to the intermolecular interactions between molecules[30].In the lower liquid mole compositions of An,the attractive force increasedthe difficulty of separation.However,the attractive force was then weakened when there are more MPC molecules,and then lead to the increase of α.Fig.9 also shows that it is more easier to get the high purity MPC from the binary system by distillation technology at lower pressures such as 2.00 kPa than at higher pressures.This is because that reducing the pressure can overcome the attraction force between the two substances.

Table 4 Binary parameters and RMSD of NRTL and Wilson models for the An(1)and MPC(2)systems

Table 5 Results of thermodynamic consistency tests

Fig.8.y–x diagram of the An and MPC systems at(2.00,4.00,6.00,7.00,and 8.00)kPa calculated using the NRTL model.

Fig.9.Relative volatility(α)of An and MPC at(2.00,4.00,6.00,7.00,and 8.00)kPa.

Furthermore,to understand the nonideality of the binary systems studied,the excess Gibbs free energies GEwere evaluated from the following equation[26]:

where γ1represents the activity coefficient,which can be evaluated from the corresponding activity coefficient model.

The variation of GEwith the composition of An and MPC is plotted in Fig.10.As can be seen,the positive deviations behavior from the Raoult's law was observed for the binary systems of the An and MPC at(6.00,7.00 and 8.00)kPa over the whole composition range.Furthermore,excess Gibbs free energy functions exhibit positive values for 2.00 kPa from(0 to 0.40)and 4.00 Pa from(0 to 0.75)respectively.

Fig.10.Calculated excess Gibbs free energy from NRTL model against liquid molar composition for the binary system of An and MPC:

4.Conclusions

A new vapor pressure of MPC has been measured by the quasi-static ebulliometric method,and the Antoine constants of the MPC were regressed from experimental data.Furthermore,the isobaric VLE data for the An and MPC system has been determined at(2.00,4.00,6.00,7.00,and8.00)kPa by the same method well.The An and MPC system could be described well by NRTL and Wilson models.According to the RMSD data,the prediction accuracy of the NRTL model is found the same as the Wilson model.Moreover,the relative volatility is far higher than 1.Thus,the conclusion can be drawn that the heat-sensitive materials MPC with high purity can be purified from the An and MPC binary system by distillation process at low pressures.

[1]X.M.Cui,Y.Nie,Supply/demand situation and development prospect of MDI at home and abroad,Chem.Ind.33(2)(2015)53–57(in Chinese).

[2]O.Kreye,H.Mutlu,M.A.Meier,Sustainable routes to polyurethane precursors,Green Chem.15(6)(2013)1431–1455.

[3]F.Paul,Catalytic synthesis of isocyanates or carbamates from nitroaromatics using group VIII transition metal catalysts.Coordin,Chem.Rev.203(2000)269–323.

[4]H.L.An,L.L.Zhang,B.G.Yuan,X.Q.Zhao,Y.J.Wang,In fl uence of solvent on reaction path to synthesis of methyl N-phenyl carbamate from aniline,CO2and methanol,Chin.J.Chem.Eng.22(5)(2014)607–610.

[5]F.Li,W.B.Li,J.Li,W.Xue,Y.J.Wang,X.Q.Zhao,Investigation of supported Zn(OAc)2catalyst and its stability in N-phenyl carbamate synthesis,Appl.Catal.A Gen.475(2014)355–362.

[6]Y.Wang,B.Liu,Efficient and recyclable heterogeneous zinc alkyl carboxylate catalyst for the synthesis of N-phenyl carbamate from aniline and dimethylcarbonate,Catal.Sci.Technol.5(1)(2015)109–113.

[7]B.Zhao,S.J.Yao,H.L.An,X.Q.Zhao,Y.J.Wang,One-pot synthesis of methyl N-phenyl carbamate from aniline,carbon dioxide and methanol,J.Chem.Technol.Biotechnol.89(10)(2014)1553–1558.

[8]M.S.Yalfani,G.Lolli,T.E.Müller,A.Wolf,L.Mleczko,Methyl N-phenyl carbamate synthesis from aniline and methyl formate:Carbon recycling to chemical products,ChemSusChem 8(3)(2015)443–447.

[9]D.H. Xu, H.Q. Li, Z.B. Li, Determination and modeling of isobaric vapor–liquid equilibria for the methylcarbamate + methyl-N-phenyl carbamate system at different pressures, J. Chem. Eng. Data 58 (11) (2013) 3110–3117.

[10]X.Q.Zhao,L.J.Kang,N.Wang,H.L.An,F.Li,Y.J.Wang,Synthesis of methyl N-phenyl carbamate catalyzed by ionic liquid-promoted zinc acetate,Ind.Eng.Chem.Res.51(35)(2012)11335–11340.

[11]J.W.Wang,Q.F.Li,W.S.Dong,M.Q.Kang,X.K.Wang,S.Y.Peng,A new non-phosgene route for synthesis of methyl N-phenyl carbamate from phenylurea and methanol,Appl.Catal.A Gen.261(2)(2004)191–195.

[12]G.Y.Zhu,H.Q.Li,Y.Cao,H.T.Liu,X.T.Li,J.Q.Chen,Q.Tang,Kinetic study on the novel efficient clean decomposition of methyl n-phenyl carbamate to phenyl isocyanate,Ind.Eng.Chem.Res.52(2013)4450–4454.

[13]B.E.Poling,G.H.Thomson,D.G.Friend,R.L.Rowley,W.V.Wilding,Vapor pressures of pure substances,Perry's chemical Engineers' handbook:Physical and chemical data,eighth ed.McGraw-Hill,New York 2007,pp.2-55–2-79.

[14]G.Li,Z.B.Li,E.Asselin,Determination and modeling of vapor–liquid equilibria for the sulfuric acid+water+butyl acetate+ethanol system,Ind.Eng.Chem.Res.52(9)(2013)3481–3489.

[15]H. Matsuda, H. Yamada, R. Takahashi, A. Koda, K. Kurihara, K. Tochigi, K. Ochi, Ebulliometric determination and prediction of vapor–liquid equilibria for binarymixtures of ethanol and ethyl hexanoate, J. Chem. Eng. Data 56 (12) (2011) 5045–5051.

[16]G.Li,Z.B.Li,Determination and prediction of vapor–liquid equilibria for a system containing water+butyl acetate+cyclohexane+ethanol,J.Chem.Eng.Data 57(2012)2543–2548.

[17]R.R.Chen,H.Ding,M.C.Liu,J.L.Qi,H.Zhou,N.Chen,Isobaricvapor–liquidequilibrium for binary system of methyl myristate+methyl palmitate at 0.5,1.0 and 1.4 kPa,Fluid Phase Equilib.382(2014)133–138.

[18]L.Zhang,C.G.Yuan,Z.Z.Sun,The synthesis of methyl N-phenyl carbamate(MPC)from diphenylurea and dimethyl carbonate,Synth.Technol.Appl.1(2006)27–29(in Chinese).

[19]C.M.Wang,H.R.Li,L.H.Zhu,S.J.Han,Isothermal and isobaric vapor+liquid equilibria of N,N-dimethyl for mamide+n-propanol+n-butanol,Fluid Phase Equilib.189(1)(2001)119–127.

[20]Y.Lei,H.R.Li,L.H.Zhu,S.J.Han,Isobaric vapor–liquid equilibria of the binary mixtures 2-methyl-3-buten-2-ol+ethanol and 2-methyl-3-buten-2-ol+1-butanol,Fluid Phase Equilib.206(1)(2003)87–94.

[21]G.B.Yao,Z.P.Yang,B.Zhang,H.Xu,H.K.Zhao,Vapor pressure and isobaric vapor–liquid equilibrium for dichloronitrobenzene isomers,Fluid Phase Equilib.367(2014)103–108.

[22]J.M.Smith,H.C.Van Ness,M.M.Abbott,Summability equation as a mixing rule,Introduction to chemical engineering thermodynamics,seventh ed.McGraw-Hill,New York 2004,pp.569–575.

[23]H.Renon,J.M.Prausnitz,Local compositions in thermodynamic excess functions for liquid mixtures,AIChE J.14(1968)135–144.

[24]Aspentech,Binary parameters(WILSON,NRTL,UNIQ),Aspen property system:Physical property methods and models V7.2,Aspentech Inc.,Burlington,MA 2010,pp.231–232.

[25]G.M.Wilson,Vapor–liquid equilibrium.XI.A new expression for the excess free energy of mixing,J.Am.Chem.Soc.86(1964)127–130.

[26]S.Han,G.B.Yao,Y.H.Zhong,C.B.Du,L.Meng,H.K.Zhao,Measurement and modeling for isobaric vapor–liquid equilibrium of binary 1,3,5-trichlorobenzene+3,5-dichloroaniline and 3-chloroaniline+3,5-dichloroaniline systems,Ind.Eng.Chem.Res.54(14)(2015)3706–3710.

[27]J.J.Ljunglin,H.C.Van Ness,Calculation of vapor–liquid equilibria from vapor pressure data,Chem.Eng.Sci.17(7)(1962)531–539.

[28]H.E.Barner,S.B.Adler,Calculation of solution nonideality from binary T–x data,Ind.Eng.Chem.Process.Des.Dev.12(1)(1973)71–75.

[29]P.F. Shen,H.Q. Li, Y.Wang,H.T. Liu, Separation simulation of productmethylN-phenyl carbamate obtained through coupled reaction, Petpetrochem. Technol. 39 (6) (2010)651–655 (in Chinese).

[30]M. Remko, V. Frecer, J. ?i?márik, MO study of molecular association of local anaesthetics of carbamate type, Collect. Czechoslov. Chem. Commun.48(2) (1983)533–537.

[31]C.C.Hu, P.H. Chiu, S.J.Wang, S.H. Cheng, Isobaric vapor–liquid equilibria for binary systems of diethyl carbonate+propylene carbonate, diethyl carbonate+propylene glycol,and ethanol + propylene carbonate at 101.3 kPa, J. Chem. Eng. Data 60 (2015)1487–1494.

Chinese Journal of Chemical Engineering2016年10期

Chinese Journal of Chemical Engineering2016年10期

- Chinese Journal of Chemical Engineering的其它文章

- CFD modeling of a headbox with injecting dilution water in a central step diffusion tube☆

- Interactions between two in-line drops rising in pure glycerin☆

- Hydrodynamics of three-phase fluidization of homogeneous ternary mixture in a conical conduit—Experimental and statistical analysis

- Adsorption of Hg(II)from aqueous solution using thiourea functionalized chelating fiber☆

- Nickel(II)removal from water using silica-based hybrid adsorbents:Fabrication and adsorption kinetics☆

- Reactive dividing wall column for hydrolysis of methyl acetate:Design and control☆